Pneumatics

Choosing the right pneumatics Gripper

Essenctials for the right usage of pneumatics in SoftGripping

Many users who are just starting to automate production and packaging lines are reluctant to use pneumatic gripper instead of electric ones. To demystify the use of pneumatics in SoftGrippers, we decided to summarize all the basic information. The topics can best be divided into the control of the compressor and the fingers.

Let’s start with the compressor: Do I need a compressor to operate a pneumatic gripper?

The short answer: Not really!

The long answer: One distinguishes between many applications:

Since the first two applications only require compressed air for short periods of operating time the fingers and thus the utilization of the compressor is rather low and you can go for a controlbox with an integrated pump. High-speed applications in contrast perform more than 60 cycles per minute. This requires a compressor that is designed for continuous operation and has a larger compressed air tank, which is used as a reservoir. The price difference can be more than an order of magnitude and exceed the cost of the gripper + controller in high-speed automation cases. A Cobot application on the other hand can be operated with an inexpensive and handy pump. So you can really choose between a high-speed controller requiring compressed air, or a all-in-one solution for slower setups. Usually, many penumatic components are used in robotic setups, so if you plan to use a valve battery with your accustomed PLC, please contact our engineers!

What does a control box contain? What are the important elements? How high must the pressure on the fingers actually be set?

Essencials in handling Pneumatics Gripper

What does a control box contain? What are the important elements? How high does the pressure at the fingers actually need to be set?

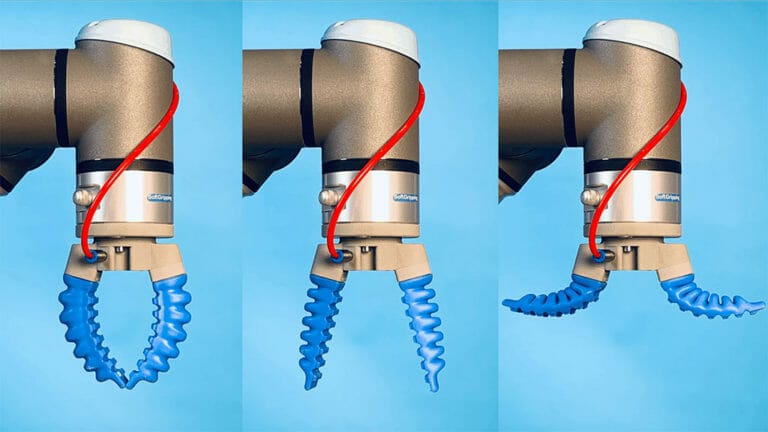

Essentially, the control box contains a suitable compressed air regulator that can maintain pressure even under static conditions, and a series of valves to switch the compressed air to the fingers. If desired, a vacuum can also be created to spread the fingers. However, unlike switching the pressure to the fingers, this involves more air consumption, especially since the consumption continues during the spreading process in order to maintain the vacuum and thus the position. During the gripping process, the finger is only pressurized once. By the way, the internal volume of the fingers can be assumed to be about 10 ml to calculate the actual consumption.

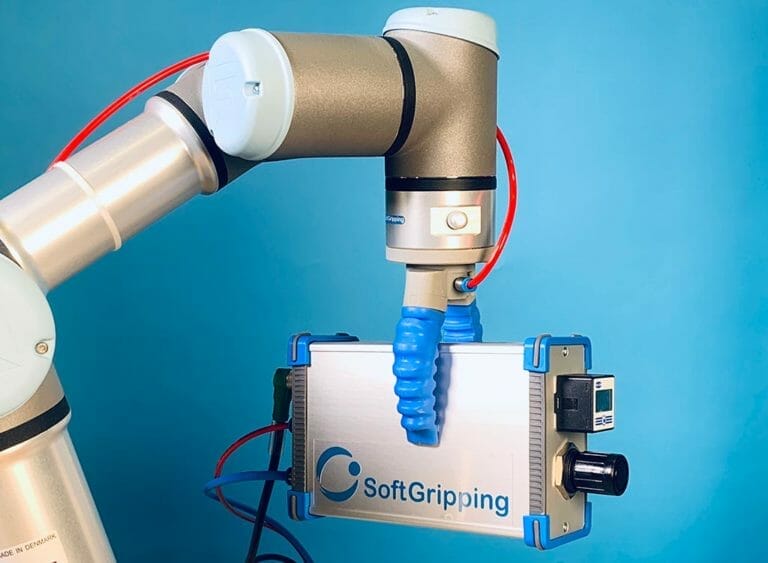

The box can be controlled by simple digital pins. If you switch a pin to high, it is either spread or closed. Neutral is when none of the pins are active. Pretty simple, isn’t it?

The pressure can be set on the box itself. But what pressure do I have to set?

Set the pressure depending on the application

This is mainly determined by the application. Big factors here are the weight of the object and its sensitivity. Some experimentation is required here. Often the first question is: How much weight can I carry with my fingers? But that’s not necessarily the significant information. In most applications, objects like potato bags are not touched. In this cases, extremely gentle handling would not be necessary. It becomes necessary when handling raw pasta, baked goods, chocolate or steaks. As a rule, nothing that weighs several kilograms. We therefore start testing with 1 bar of pressure on the fingers. As a point of reference, a ripe raspberry needs no more than 0.2 bar to be handled gentle but safely. For most applications, you can expect each finger to hold about 200 g. This numbers of course increases with higher pressure.

Do you have an application where suction cups might play a role? We cannot pick the perfect suction cup for you, but what we can offer is an integrated control – right in the control box. The suction cup itself is then simply screwed into the center of the gripper base.

If you have any questions about a particular application, our team will be happy to advise you on the best solution. So save yourself a lot of time, take advantage of our experience and contact us directly!