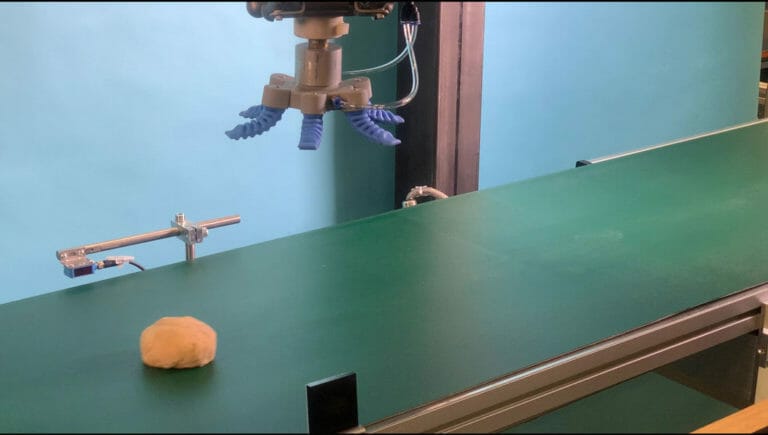

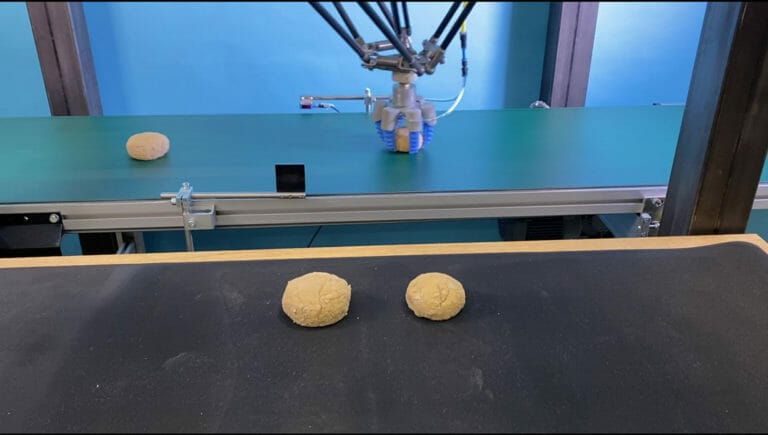

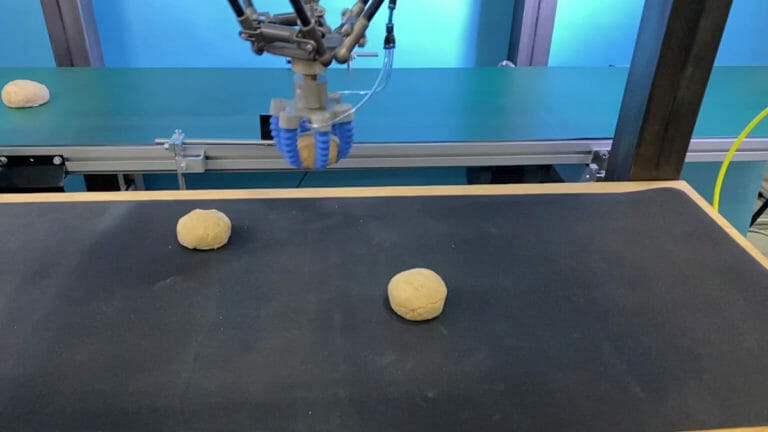

Handling raw dough using a centric SoftGripper

Application

Dough handling… Nowadays, it is a standard application for every bakery – small and large – all of them want to have this task automated to some degree. For testing this solution, two main partners were important: ESSENTIAL Robot Products and Conecta2. Each having their specific needs. While American FDA regulations are focused on hygienic design of the gripper body, partners from spain are about having a degree of variablitily to adapt a single gripper model to multiple dough types in between handling processes.

Starting from SoftActuator line, we had the measurements to develop a gripper into a full body SoftGripper model.

Of course, not only the state, structure and temperature of the single doughs was important, but speeds, accelerations and blending/smoothing corners in handling geometries.

You can find more information about this product on our shop page:

Using SoftActuators

The first step in the automation journey is having the fingers adjusted to the dough and to the variation of different doughts to be handled by the robot. Using eoat plates, fingers and angle a basic form for the dough gripper was prepared. A major focus here lied on not applying to much pressure on the dough but still have a good grasp to avoid damaging it in any way.

Using SoftGrippers

Having a full body SoftGripper for dough handling comes with a hygienic design, meaning a fast and easy cleaning process between shifts. The basic design uses fingers and base, but it can be adjusted with constructs to reduce sideway drag when the pick and place process is not optimized using smoothing of the robot traveling curves.

First videos

For a full view, we would like to present some videos of the first calibration attempts for you to see what details have to be taken care of.