SoftActuator

SoftActuators for your Own High Speed Pick And Place EOAT

Individualisation Was Never Pretty Easy Before!

SoftActuator - The Key in automation

SoftActuators are made to be used:

- For engineers who wants to build their own EOAT

- For a huge variety of objects

- For easy adjustment when the gripping objects change

- In setups for easy prototyping

Build your own base or use our versatile profiles

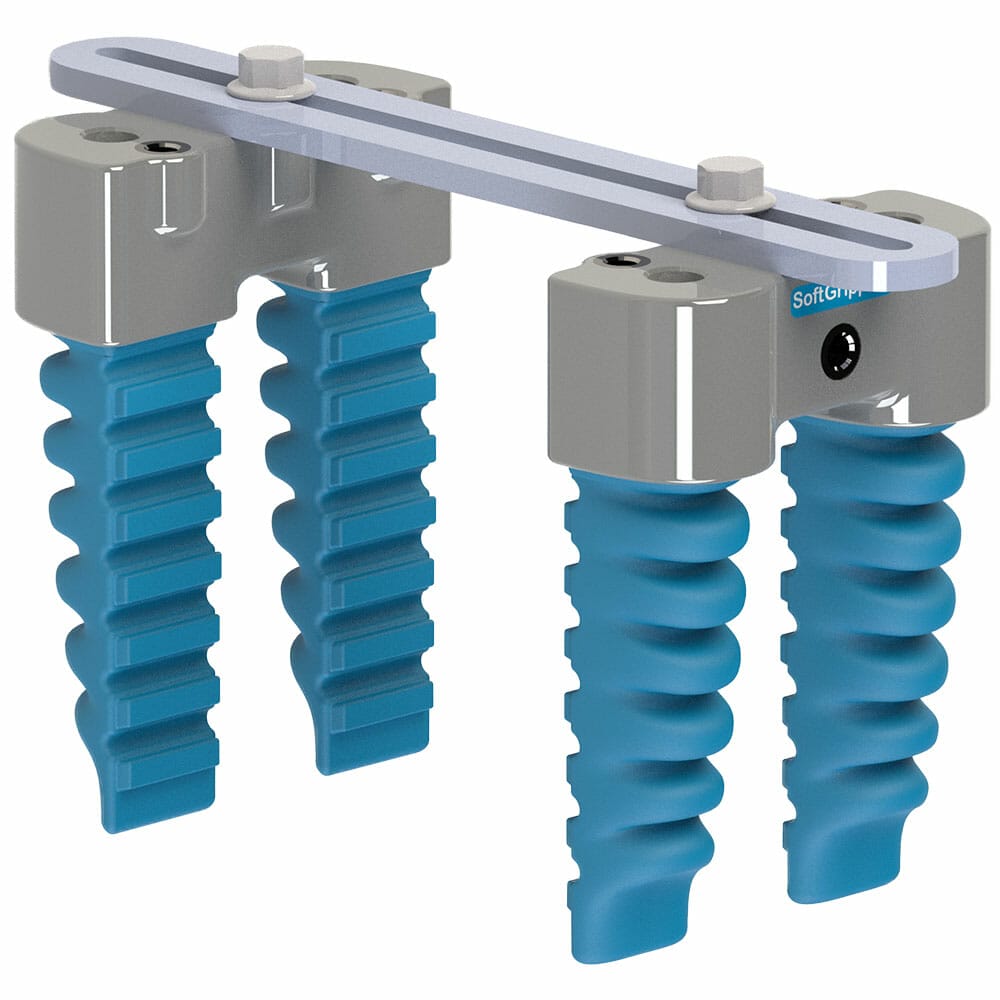

We provide the SoftActuators, you choose the shape of your base. This is really special! You can freely choose the type of your base. You like the flexibility of EOAT systems with aluminum construction profiles? You want to build your own solution with a bended plate (or we can do it for you)? You like to use our versatile profiles? Let’s talk about what you need!

Our SoftActuators are the Fingers for your gripper

Our proven pneumatically driven fingers are made of FDA-approved silicon rubber with a lifetime of more than 10 million cycles. You can mount them on every EOAT setup without the need to get a special base. Our SoftActuators are made in hygienic design.

SoftGripping Fingers and GorillaFingers

SoftGripping Fingers

SoftGripping Fingers are designed for deft handling of smaller goods and weights up to 1 kg. Basically anything you would handle with your fingertips.

Here are a few examples of how our robotic fingers can be used:

- Picking sushi

- Packaging sandwiches

- Sorting bell peppers by color into boxes

- Pick&Place of cakes and chocolates

SoftGripping GorillaFingers

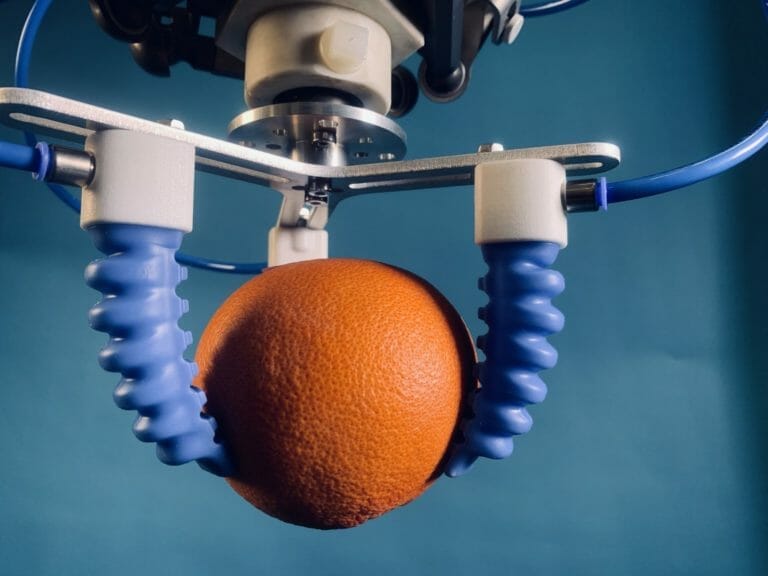

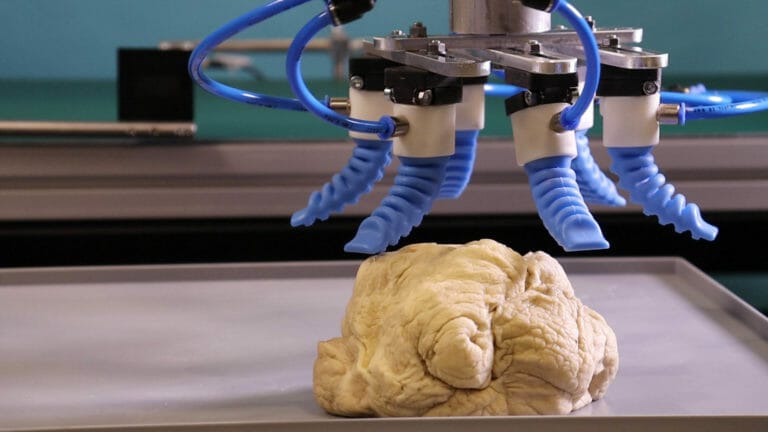

The GorillaFingers are made for handling large, bulky and heavy goods. This does not only include big fruit and vegetables like pineapple, melons or cabbages, but netted and bagged products as well. GorillaFingers can handle netted potatoes, onions and apples. Those products typically come packed in up to 3,5 kg nets or bags, but even higher loads are possible using this bigger finger variant.

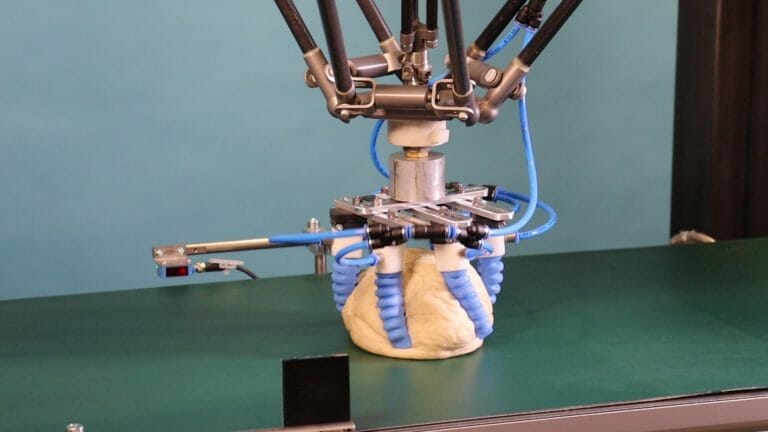

The special feature of Softgripping is that the fingers wrap around objects. For example, nets with products are often not of a particular shape and the individual goods move around inside them. Our GorillaFingers wrap around the net and the produce inside to guarantee a perfectly safe grip, even at high speed handling.

Fully control In the gripper design

SoftActuators in changing production setups

The changing of a automation setup for a different type of gripping object to be handled can be complicated. It may requires new parameters for positioning. This can be an adjustment of the TCP height to the new product, an adjustment of the distances in the tray or a calibration of the camera.

In most applications, it would also require a completely new gripper. Not with SoftActuators! Just adjust the position of the fingers at the base and move on to the next item set!

Types of SoftActuators

For maximum flexibility and variability, we offer three different SoftActuators, which are always in stock!

- 1-Finger SoftActuator

- 2-Finger SoftActuator

- 3-Finger SoftActuator

If you need something special like 4, 5, 6, 7, … fingers or actuators with a larger or smaller finger distance, we´ll build it for you within 2 weeks,

High-Speed applications with SoftActuators

Our Fingers Adapt To Your Objects

A picture says more than 1000 words a video much more. SoftActuators being used to handle multiple and versatile foods in one gripper setup. Simple adjustments of spacing and angles of the SoftActuators leads to a wide range of objects being gripped within one gripper setup. Using our profiles with slot holes for your setup, when packaged foods are handled. The SoftActuators are mounted using standard screws and can be used in any gripper setup, also for special bases in hygienic design.

Don’t forget to keep in mind that pneumatic valves are required to operate the SoftActuator finger actuators. Use your own pneumatic system or check out our Controlbox.

For more information and instructions, please contact us!

Benefits Of An SoftActuator

- Hygienic Design

- FDA approved material for our silicon rubber fingers and finger mounts

- Extremely light setup for maximum acceleration and speed

- Suitable for very small to very large objects

- Highly modular for your individual application

-

Extraordinary optimized pneumatics with our Controlbox for high-speed cycling

- We like to build your individual solution! It will be ready for shipping within 2 weeks

Example Grippers with SoftActuators

Maximum Variations For Maximal Diversity Of Gripping Objects

Why use SoftActuators?

SoftActuators As A Standard Component In Automation

A component for rapid gripper prototyping

SoftActuators are a perfect complement to standard components such as suction cups and linear actuators to form the moving elements such as grippers that ultimately handle goods in automatic setups.

Using Soft Actuators in EoAT setups

You need to pick up multiple products and place them on a tray and use multiple tools with one multigripper? A solution would be an end of arm tooling (eoat) with multiple suction cups, fingers and pneumatic elements.

Angle Adapter

Expands The Possibilities

If you need to grip your object in a special angle, use our SoftActuators Angle Adapter. No Limits with SoftGripping!

Consideration

We have encountered applications from food packaging to picking scrape metal from automobile parts and our scope of application only broadens. Therefore, we are confident in our ability to find the best solution to your gripping problem.

Contact

Please feel free to get in touch via email or phone so we can help you to find the right tool!

Industrial robots

- Tailor-made for your application

- Use arrays or adapters with your carrier plate creations

- Ask for our plate service