A Comprehensive Guide To Grippers

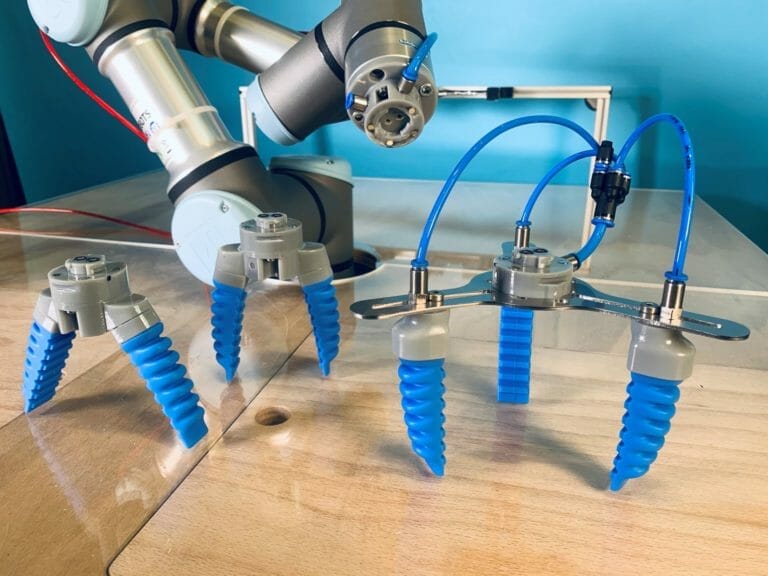

Configuring the right SoftGripper for a robot

What Is A Gripper?

To put it in the simplest way possible, a gripper is a device that enables robots to interact with objects such as picking, holding, and moving them safely. When grippers are combined with collaborative robotic arms, they aid in automating critical manufacturing processes such as assembly, inspection, picking and placing, and machine tending.

Gripper Types

Even though all grippers essentially perform the same function, you can have several different designs and forms depending on how you are going to use them.

Vacuum Grippers

These use the difference between a vacuum and atmospheric pressure to hold objects, lift them, and ultimately move them to the desired station. A compressed air-driven or mini electromechanical pump generates the vacuum flow that helps the gripper hold and lift objects.

Vacuum grippers that use compressed air-type pumps are more suitable for heavy objects. That’s because these pumps produce four to ten times additional power than electromechanical pumps.

Moreover, they aid in automating many procedures, but they are most commonly used for palletizing (stacking and packing items on a pallet) and packaging. Additionally, they can handle various types of products, no matter how they are positioned. Compared to different gripper types, they are more affordable.

The main disadvantages of vacuum grippers are that they are sensitive to dust and the cost of electricity to power vacuum or compressed air pumps is high. They have very special requirements for the surface of the gripping objects to hold them safely. They doesn´t work with every type of object.

Pneumatic Grippers

They use pistons and compressed air to maneuver the ‘jaws’ or ‘fingers’ and are known for their versatility. The pneumatic grippers are usually available with two or three-finger grips.

The benefits of pneumatic grippers are that they do not cost as much as other grippers, operate within tight spaces, and have a fast response time. The downside of using pneumatic grips is that they can only handle single-part objects, which makes them unsuitable for facilities that have high mix/low volume items. Pneumatic grippers also have limited position and force control and can only function using compressed air.

A special type of pneumatic grippers are grippers with soft structures and surfaces, the SoftGripper by SoftGripping. With their adaptable surface they can grip and hold a wide range of products safely and gently. They are perfect for food handling and for objects which needs to be handled very carefully. In the food sector, they´re used as meat gripper, fish gripper, egg gripper, salat gripper, bread gripper, fruit gripper for strawberries, rasperry, apples or bananas for example. They´re are also used as gripper for medical products or electric components.

Hydraulic Grippers

Hydraulic grippers are heavy-duty, meaning that they have higher gripping power than pneumatic grippers. They receive this power through hydraulic fluids.

The main benefit of using a hydraulic gripper is that they have great gripping power. The con is also their high gripping power can be used only for a very special range of applications. Those grippers needs complex handling of oil, pumps, and reservoirs. Because of this, they are high maintenance and cannot be used diverse applications. The risk of leakage is a problem for the handling of foods and medical products.

Electric Grippers

Electric grippers are commonly used for collaborative robotic applications such as pick and place and machine tending. They may not have the gripping power that hydraulic grippers have, but they are suitable for tasks requiring a light gripping force and high speed.

They usually come in two and three-finger configurations, and the three-finger grippers are often used to handle round or cylindrical objects.

The main reason electric grippers are preferred when automating manufacturing processes is that they provide control. Electric grippers usually have microprocessors installed to help users set speed and gripping force according to the task at hand. The force sensor is the reason that these grippers can handle different types of parts with ease.

The main disadvantages of using electric grippers are that they grip with less force than hydraulic or even pneumatic grips and can also be quite costly. It can be difficult to grip soft and sensitive objects because of their mostly hard surfaces.

Magnetic Grippers

Magnetic grippers are used to grip ferromagnetic materials safely. They use the magnetic field generated by integrated permanent magnets. These magnets are then moved using compressed air to control the grip. Magnetic grips use pneumatic valves to operate and thus do not need voltage to work.

Parallel Vs. Centric Grippers

There are several differences between two and three-finger grippers and different types within these gripper configurations. Let’s explore each one in detail.

Two and more Fingered Parallel Grippers

As the name suggests, these grippers use parallel finger or jaw configurations to handle payloads.

Parallel grippers can be actuating using hydraulic, pneumatic, or electrical power. The fingers are parallel to one another, and they close in to hold onto an object in that way.

Due to their design, conventional parallel jaw or finger grippers can only grasp items in a pinching motion, meaning that they are rigid and limited in their use. Parallel grippers usually cannot be adjust to the shapes of different objects. In this case, they can grip and handle only specific products. Custom jaws that need to be produced if other objects are controlled using this gripper.

The other kind of two-fingered gripper is the adaptive gripper SoftGripper by SoftGripping. These are more advanced than conventional parallel grippers and can be used in more ways. As the name suggests, these grippers are highly adaptable and can be used to grasp objects no matter their shape (cylindrical, rectangular, etc.)

The adaptive gripper automatically repositions itself to change if the object’s shape in the production line changes.

Parallel grippers are also available with more than two fingers. If very heavy or very long objects has to be gripped, than it will be necessary to use a four, six, eight or more fingered parallel gripper.

Parallel grippers are primarily used to hold rectangular or cuboid objects, but also cylindrical objects if they´re gripped not from the top or the buttom.

Three Fingered and Four Fingered Centric Grippers

Mostly centric grippers are ‘self-centering,’ meaning they close centrally and grab the cylindric parts centrally. These usually function using pneumatic or for special heavy weight applications hydraulic energy. Even though they can carry more significant weights by gripping a cylindric object at the center of gravity, they are not that flexible like parallel grippers regarding the diversity of geometrical shapes and sizes of grippable objects.

Adaptive centric three-fingered and four-fingered gripper like SoftGripper allows for better flexibility and reliability when gripping objects different shapes and sizes. SoftGripper have three modes: wide open using vacuum, relaxed without overpressure or vacuum, and grip by using overpressure. Various applications can utilize these three modes to perform the gripping tasks successfully. With this function and the adaptive properties, small objects can be gripped like large objects only with one SoftGripper.

Adaptive three-fingered grippers are incredibly flexible and can be used for various applications. Industrial tasks like machine tending and food handling with round objects like apples, oranges, eggs, melon are ones of the diverse tasks range for centric grippers.

Centric grippers are mainly used for triangular, round or cylindrical objects.

Which Grippers Are More Error-Forgiving?

Conventional jaw grippers can handle objects safely and without many failures. To do this, however, the objects must always be positioned very precisely or gripped very accurately. The object structure must not change and the gripper must be specially manufactured for this purpose. Otherwise, faulty gripping processes will occur and the entire upstream and downstream process may come to a standstill.

Adaptive grippers are more forgiving of positioning or object detection requirements and more versatile when gripping different objects with just one gripper.

Internal, External, Or Combined

There are two main styles in which the grippers hold an object, and they are:

Internal

To put it simply, the gripper holds the object internally if there is enough space within and a solid surface to grasp on to. The gripper uses its opening force to hold on to the part.

External

Most commonly, external gripping is used so that it is easier to hold and move parts. External gripping works when the fingers of the gripper close around the outside of the needed part.

Combined

Some grippers can be used for both internal and external grips. These grippers are usually more flexible and can adapt according to the object. SoftGripper can be used with vacuum for the internal grip and overpressure for the external grip.

What Is A Soft Gripper?

Automated devices are being introduced in various sectors, and cobot (collaborative robot) systems are needed to perform in dangerous or simple tasks or for supporting human workers. This is where soft grippers come in. They´re the perfect choise for high speed pick and place applications with delta robotics and for cobots. Soft grippers are created from compliant materials and powered through the use of compressed air.

Where Do You Need Soft Gripping?

Soft grippers are in high demand. They can automate the packaging and harvesting of vegetables and fruits due to their delicate touch. Many e-commerce warehouses use soft grippers to pick up packages and parts of different sizes, weights, and shapes.

They can also be used in environments where it is dangerous for humans to work, such as research and development labs.

Soft-gripping.com

SoftGripping by Wegard GmbH has created various soft grippers that can be used in many different ways.

SoftGripping has four product lines: Cobot grippers for Cobot applications, industrial grippers for high speed delta and scara robotics, hygienic grippers comes in a special hygienic design for meat and fish handling and educational grippers with a maximum modular design for education or research and development.

The SoftGripping cobot grippers can be adjusted to every cobot systems. These grippers have the same proven and unique flexible fingers like the other gripper from SoftGripping. The finger bases are specially designed for cobots. They do not have sharp edges and are hazard-free, making them the perfect work companion.

The materials of finger and bases are FDA approved both the bases and fingers, meaning they can be used to handle food items. The cobot grippers use enough force to hold the desired object firmly, but its soft material ensures that the product is dealt with gently.

SoftGripping’s industrial grippers are lightweight to ensure maximum speed and acceleration. Due to the modular design, these grippers can be used to handle both tiny and giant objects – SoftGripping build the perfect gripper for your requirements. The finger arrays with one up to four fingers can be mounted on versatile bases made of lightweight plastic, steel plates or aluminium profiles allow for quick finger position adjustment. They can be tailor-made for different applications, and their high flexibility makes them perfect for individual applications. These grippers use optimized pneumatics to work efficiently, quickly, and effectively for industrial purposes.

Softgripping has created grippers that exceed the hygiene requirements imposed on certain foods. The screws holding the gripper parts are all hygienic, and the parts can easily be removed for cleaning. All parts are very sturdy and can be cleaned with industrial quality cleaning agents while being pressure washed.

For the pneumatics process to be kept hygienic, the fingers are supplied the energy through an established connection to the base place with a single input. The pneumatics are of a good size, meaning that the fastest cobots can use the hygienic gripper system in the market.

These hygienic grippers are perfect for food items like sausage, fish, meat fillets, cheese, bread, and buns. They are highly adaptable and designed according to hygienic design specifications. A lesser amount of elements are used. The proven bayonet locks of SoftGripping cobot and industrial grippers have been replaced with special hygienic locks.

SoftGripping has created a highly flexible Construction Kit, which can be used for educational purposes, conducting experiments, and further testing and innovation in the gripping products industry. The perfect gripping system for research and development.

When studying robotics, grippers need to be changed frequently to apply them in different situations. SoftGripping’s construction kit allows users to adjust the angle and position of the gripping fingers in a matter of seconds. The bayonet lock used within this system makes changing components fast and easy.

Areas of Application

SoftGripper can be used to perform a myriad of tasks within different industries. Here are some areas of application that soft grippers can cater to.

Food Management, Logistics and Packaging

Due to advancements in gripper industry, many food-management-related processes have become automated. Soft grippers can gently but firmly tend to most mass-produced food items no matter their size or weight.

From bakery treats to marshmallows and chocolate, soft grippers have revolutionized the handling in food industry. Automation has made it easier for food manufacturers to create food items in bulk.

Grippers are also heavily used in the logistics industry. They are applied in logistics for storage purposes and picking in online retailing.

Harvesting and Recycling

Soft gripping is a critical component in ‘smart farming.’ Many farmers are incorporating robotics to make farming more manageable, efficient, and less time-consuming. Soft gripping allows users to gently pick up or harvest different fruits and vegetables such as tomatoes and berries.

Recycling separation has also now been automated through the use of soft grippers.

Assembly Line Production and Sorting

One of the most popular uses for grippers is in assembly-line production. There is a lot of sorting and moving of materials and products in a production line, so to assemble them both precisely and quickly, soft grippers like SoftGripping are perfect.

Similarly, grippers can be used to sort different products and separate them accordingly.

Cost of Grippers

The cost of grippers varies according to the following factors:

- What gripping unit and how many fingers you want to get

- Whether you need tool changers and different grippers

- Whether your gripper will need to be custom-made

Ongoing Costs

You’ll also need to account for the overhead costs of operating a gripping unit. These include:

- How often will it need to be maintained, and how much will it cost to maintain

- Cost of energy needed to power the gripper of your choice

Lifespan Of A Gripper

The durability of grippers is very different. Soft grippers from SoftGripping have a lifespan of 10.000.000 cycles (at 1 bar operating pressure).

Life Span Of SoftGripping’s Products

Apart from the quality and innovative design, Soft-gripping’s grippers have another huge upside. SoftGripping guarantees 10 million cycles (at 1 bar operating pressure), which is quite extraordinary compared to other grippers.

Which Gripper Is The Right One For My Requirements?

There are many things to consider when choosing a robotic gripper. But the way to know which gripper will work best for you is by narrowing down the specific applications you need it for. Here are a few ways to know which gripper will work best for you:

- Do you need a gripper that handles single items or mixed ones? A simple two-fingered parallel gripper can work for single items, and a four-fingered soft gripper could work wonderfully for a mix of different things.

- Would your gripper be operating in a small, tight space? Pneumatic soft grippers with an small base could work well in such conditions.

- What type of items will be handled by the grippers? If they are food items, a SoftGripping gripper would be the way to go. Maybe in special hygienic design. For electrical components, you could go for an industrial gripper from SoftGripping.

- The shape of the items that the grippers will handle must be taken into consideration. For curved or irregularly shaped items, a soft gripper is the right choice. They adapt to any surface and shape.

- Do you need to use the gripper in a medical or cleanroom environment? If that is the case, it is essential to go for a hygienic gripper.

- To know the number of fingers, you should go for, consider the payload you would like the gripper to handle. The higher the load the more fingers are needed.

FAQs

Can A Gripper Drop Parts?

Grippers are made to be powerful and stable, acting just like our fingers. If you use the gripper correctly, they will not drop any objects or parts you use them with.

Can A Gripper Be Tailor-Made?

The short answer: yes! SoftGripping ensures that the gripper you need is the gripper you get, and it can be customized in any way you like. Sky’s the limit.

What Is A Bayonet Lock?

A bayonet lock is a mount for the fingers to be attached to the gripper base. It helps to easily attach and detach the fingers from the gripping unit as needed.

The arrays have our unique bayonet lock to mount and unmount the fingers with one hand in a second.