Soft Robotics vs. Hard Robotics – Comparative Insights and Analysis

Table of Contents

Meanwhile, hard robotics involves the construction of robots using rigid and solid materials. These robots are often seen in industrial settings, performing tasks that require strength and precision. So, with that said, in this blog, we will study soft and hard robotics, exploring their origin, applications, pros and cons, and highlighting their key differences.

Origins Of Soft Robotics

Soft robotics has its roots in the early 1990s. Researchers began experimenting with the idea of creating robots that had flexible and deformable structures. So, the researchers wanted to develop robots that could interact more naturally with humans and operate in complex environments. And to achieve this, scientists drew inspiration from nature. They started studying how animals move and soft-bodied organisms behave.

A powerful breakthrough in soft robotics came with the introduction of elastomeric materials and flexible sensors. These materials, like silicone-based polymers, hydrogels, and shape-memory alloys, provide the necessary flexibility and stretchability to build soft robotic systems. In that way, advancements in soft actuators, such as pneumatic artificial muscles and dielectric elastomer actuators, allowed robots to mimic natural movements more effectively.

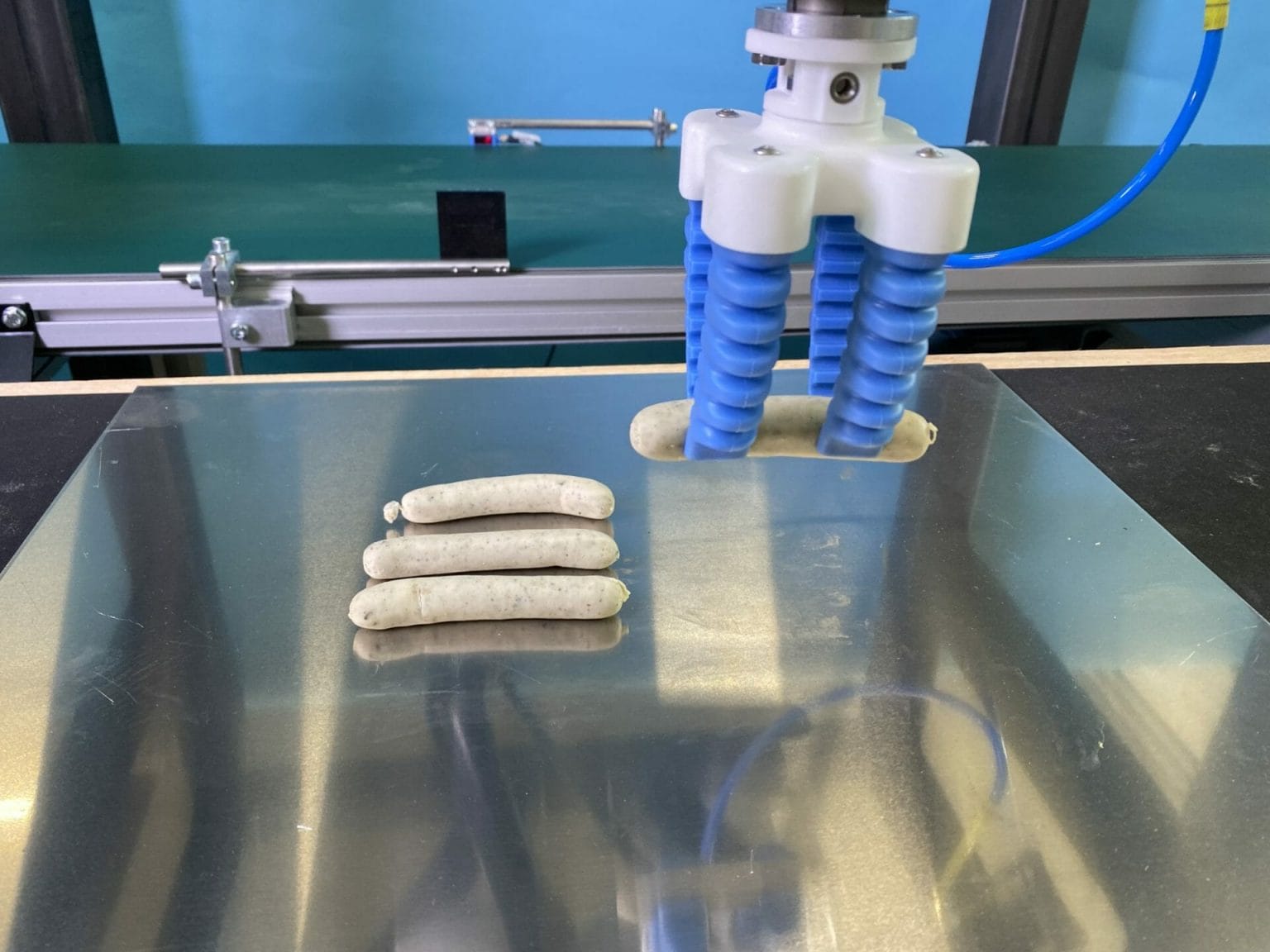

As soft robotics gained recognition and attention, notable progress has been made in various areas. Researchers have developed soft robots for tasks such as gripping and manipulating objects, moving around, assisting in surgeries, and exploring challenging environments. The field continues to evolve through ongoing research, advancements in materials, and the integration of new technologies. It includes sensors, artificial intelligence, and machine learning.

Today, soft robotics is a dynamic and broad field with many research groups, conferences, and publications. They all are dedicated to exploring the principles and applications of soft robotic systems. It could transform industries like healthcare, manufacturing, and agriculture. It offers safe and versatile robotic solutions that can work in dynamic and unpredictable environments.

Origins Of Hard Robotics

Hard robotics was invented in the mid-20th century by introducing industrial robots like Unimate. These powerful machines were designed for tasks such as welding and material handling. Advancements in materials and control systems have since contributed to the evolution of robust robots. They are experts in industries like automotive manufacturing and construction. Hard robotics has arisen as a driving force behind automation and technological advancements. With rigid structures and precise control mechanisms, hard robots are transforming industries. They provide unmatched precision, strength, and efficiency.

Characteristics Of Soft And Hard Robotics Systems

Here are some of the main characteristics of soft and hard robotics.

Soft Robotics

- They are made with flexible, stretchable materials with reversible and variable properties.

- Soft robotics have inherent compliance matching the environment.

- Continuum topology with infinite degrees of freedom (DoF) housing essential elements.

- They are inherently safe, adaptive, and tolerant to operate in unknown environments, especially for human-machine interaction.

- Flexible and stretchable electronics and power sources.

- High-level behavioural diversity, high level of bio-inspiration, can tolerate low accuracy, low speed, and force applications, and is of low weight and cost.

Hard Robotics

- Hard robotics are made with materials with invariable properties.

- Advanced feedback control strategies and sensors facilitate its smooth contact with the environment.

- Discrete topology with finite freedom consisting of rigid elements connected by single DoF joints.

- Considered unsafe and intolerant with limited adaptability to operate in unknown environments unless intricate control measures are applied.

- Hard robotics have conventional electronics and power sources.

- Low level of behavioural diversity, low level of bio-inspiration, high accuracy, high speed and force application, and high weight and cost.

Soft Robotics Vs. Hard Robotics-Main Differences

There are two different methods for designing and implementing robotic systems. They are hard robotics and soft robotics. Both robotics attempt to perform automation and carry out many activities. But they are very different in terms of their structural features, functionalities, and applications. In that regard, here are some of the main differences between soft and hard robotics.

Structural Flexibility

Soft and flexible materials, like elastomers, hydrogels, and flexible polymers, are used in soft robotics. And it is distinguished by its flexibility and compliance. Hard robotics, in contrast, uses stiff components made of metal, hard plastic, and other non-flexible materials. Soft robots can deform, bend, and stretch. It improves their ability to interact with their environment and adapt to it. Meanwhile, hard robots, on the other hand, have rigid constructions that restrict their flexibility.

Safe Human Interaction

Soft robots, especially those that may be placed near people, are intrinsically safer to engage with. Soft robots are excellent for situations where human-robot collaboration is required because of their compliance and flexibility, which reduces the danger of damage or harm. Hard robots, conversely, can present significant concerns due to their stiff construction and the need for additional safety precautions when used in conjunction with people.

Precision and Strength

Hard robots best perform tasks requiring extreme strength and accuracy. They can perform accurate and controlled motions because of their sturdy construction and precision control systems. Hard robots are frequently utilized in manufacturing, assembly lines, and operations requiring heavy lifting, welding, or precision placement. Soft robots provide special skills in activities that need sensitive interactions, delicate handling, or the capacity to adapt to unstructured situations, despite being less exact and often less strong than hard robots.

Versatility and Adaptability

In comparison to hard robotics, soft robots are more versatile and adaptable. They can move through complicated, chaotic situations more successfully. Thanks to their compliance and flexible structures. Soft robots can handle things of diverse shapes and sizes. They can fit into small areas and adapt to varied surfaces. Hard robots, in contrast, may need adaptations to complete tasks in complex or dynamic contexts. Hard robots are often less flexible to changing circumstances.

Applications Of Soft Robotics

- Soft robotics has found applications in various areas like healthcare, exploration, and even how humans and robots work together. Soft robots are great at tasks that require gentle movements, handling delicate objects, and collaborating safely with humans.

- They have transformed the medical field, helping in minimally invasive surgeries. They can navigate intricate anatomical structures without causing damage. Also, they show promise in search and rescue missions, accessing hard-to-reach areas and locating survivors. Their versatility is truly remarkable.

- Bio-inspired robotics draws inspiration from biological systems to design robots with enhanced capabilities. Soft robotics enhances human-robot interaction. It makes physical interactions safer and more intuitive. It holds immense potential in social robots, education, and entertainment.

- In agriculture, soft robotics can handle delicate crops, while in manufacturing, they excel at intricate assembly tasks. With the agricultural industry facing labour shortages and the need for sustainability, soft robotics provides innovative solutions. It enhances efficiency, reduces labour requirements, and boosts crop productivity.

- Soft robotics is ideal for delicate crop handling. It minimizes damage and waste. Soft grippers with compliant materials adjust to crop shapes, ensuring precise and careful harvesting. This gentle touch reduces crop damage, improving quality and decreasing losses. Soft robotics plays a vital role in enhancing efficiency and sustainability in agriculture. Bio-inspired grippers aim to enhance the capabilities and adaptability of robotic manipulation in different applications.

- Soft robotics offers precise weed control, reducing reliance on herbicides. Soft robots navigate crop rows, selectively removing weeds without damaging desired plants. This targeted approach improves crop yields and promotes sustainable farming. Soft robotics addresses declining pollinator populations by providing artificial pollination support. Bee-like robots aid in pollination, enhancing crop yields and ensuring agricultural sustainability.

- Soft robotics plays a vital role in monitoring crop health and collecting valuable data for precision farming. Equipped with sensors, soft robotic systems navigate fields, providing real-time soil moisture, temperature, and crop growth data. This information helps optimize resource utilization. It minimizes environmental impact and enables early detection of diseases or nutrient deficiencies for improved crop health.

Application Of Hard Robotics

- Hard robotics is widely used in industries. It includes manufacturing, construction, and automotive assembly. These industries need robots with precise movements, strength, and control. Hard robots are designed with rigid structures made of metals and hard plastics. It gives them stability and the ability to exert high levels of force. Bio-inspired robotics is revolutionizing industries with its precise control mechanisms and bio-inspired design.

- Hard robotics is all about achieving unmatched precision. As it is built with sturdy materials, these robots handle heavy loads and perform tasks that require exactitude. In manufacturing, they shine in assembly line operations, welding, painting, and quality inspection, enhancing efficiency and maintaining high standards. Hard robotics is revolutionizing industries with its precise control mechanisms and bio-inspired design. These robots offer unmatched precision, strength, and efficiency, driving automation and technological advancements.

- Hard robotics drives industrial automation, enhancing production efficiency globally. With speed, strength, and accuracy, hard robots perform repetitive tasks precisely, minimizing errors and increasing productivity. The automotive industry, in particular, extensively utilizes hard robotics in car assembly lines and manufacturing processes, reaping significant benefits. Moreover, hard robotics has revolutionized healthcare, particularly in surgical procedures. Robotic-assisted surgery enhances precision, control, and skill, leading to optimal outcomes, reduced invasiveness, and faster patient recovery. Hard robots are essential in dangerous or unsafe environments.

- Equipped with specialized sensors and protective enclosures, they perform critical tasks in hazardous places. It can be like nuclear facilities or disaster areas. Their rugged design ensures operator safety while performing inspection, maintenance, and disaster recovery. Hard robotics has greatly benefited the logistics and warehousing industry. These robots excel in material handling, palletizing, packaging, and order fulfilment tasks. Equipped with advanced sensors and algorithms, they efficiently navigate warehouse environments, optimizing inventory management and reducing costs. Their presence improves accuracy, reduces labor requirements, and enhances supply chain efficiency.

- Hard robotics is a valuable tool in research and education. Institutions and labs use hard robots to teach robotics principles, programming, and engineering concepts. These hands-on experiences foster innovation and skill development, pushing the boundaries of robotic technology

Pros And Cons Of Soft And Hard Robotics

Here are some of the pros and cons of soft and hard robotics.

Pros of Soft Robotic

- Flexible and compliant materials offer adaptability and flexibility

- High adaptability to navigate unstructured or unpredictable environments

- Low-cost and easier fabrication due to simple materials and manufacturing processes

- Reduced risk of injury to humans and damage to the environment

Cons of Soft Robotics

- Limited precision and repeatability compared to hard robotics

- Higher control and power requirements compared to hard robotics

- Limited strength and durability for heavy-duty applications

- Lower load capacity, limiting suitability for heavy-duty tasks

Pros of Hard Robotics

- Rigid materials (metal, plastic) provide strength and durability

- High precision and repeatability in movement

- Relatively simple control and power requirements

- Excellent load capacity for heavy-duty applications

Cons of Hard Robotics

- Limited flexibility and adaptability compared to soft robotics

- Potential for injury to humans and damage

- Poor performance in unstructured or

- High cost and complexity in design

conclusion

In conclusion, soft robotics and hard robotics are two different fields in the world of robot design. Soft robots are all about being compliant and adaptable, perfect for those delicate tasks and interactions. On the other hand, hard robots rock with their rigid structures and precise control, tackling tasks that require strength and precision. Both fields make huge contributions to different industries. They push the limits of flexible robotic technology and create exciting possibilities for innovation and creative problem-solving. It’s an exciting time for robotics!

Contact

We are happy to get in touch with you! Let’s have a quick talk and find out how to automate your application. Our engineers will validate your application and provide you with test material in form of videos pictures and whitepapers:

More Applications

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.