GorillaFingers for bagged and netted goods

Application

Net-wrapped, packaged, or simply large and heavy foods were long considered difficult for robots to pick and place. Conventional grippers could not be used because they were either too small, could not get a good grip around the product, or would simply crush and dent the food. Soft grippers were considered the perfect solution for this task. After thorough development in collaboration with our customers, there is now a new player on the market designed specifically for bagged products: The GorillaFinger SoftGripper.

Let’s find out what makes it so special and why it is the perfect gripper for all fruits and vegetables in nets and bags and why GorillaFingers are perfect for gentle handling of all goods, even for weights up to 5 kg!

Difference between SoftGripping Fingers and GorillaFingers

At first glance they look the same, but in this case it really comes down to size. The larger GorillaFingers are not just a replacement for the SoftGripping fingers, they offer a whole new range of foods that can be handled. While the small fingers are best for individual fruits, vegetables, baked goods and any other small food item you can think of, the larger GorillaFingers are for packages of goods, not just individual products.

Imagine handling a single orange compared to handling oranges or onions packed in a net. Surely you would pack the individual oranges one by one in a box with limited space available using a standard SoftGripping Finger. With GorillaFingers, the space requirement is higher, but in this case you would take the freshly packed nets off the conveyor belt and place them in a box for transport.

Different applications of SoftGripping Fingers and GorillaFingers

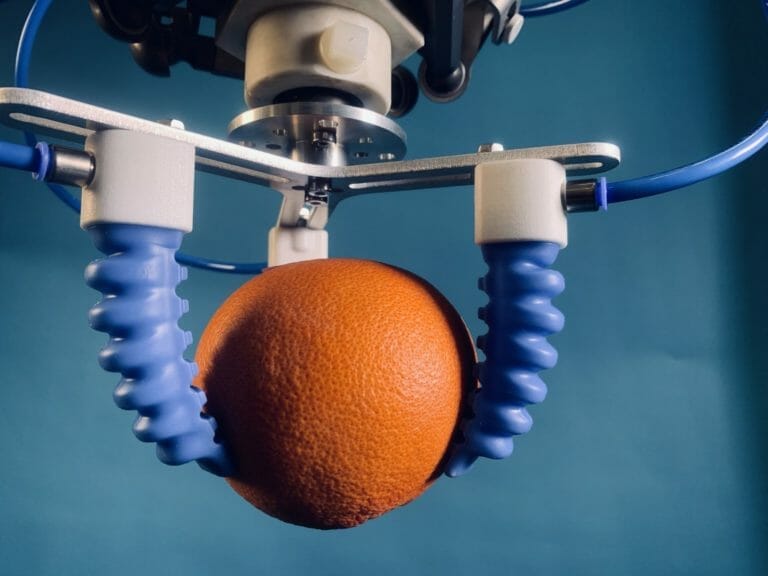

These two pictures show the difference: SoftGripping Fingers handling an orange of approx. 200 g versus the larger GorillaFinger variant handling a 2 kg onion net. In both cases, the SoftActuator platform is used, i.e. the individual adapters are placed on metal plates that allow the fingers to adapt quickly to the task at hand. This means that smaller or larger objects can be handled with a single gripper. This is useful for choosing automation configurations or using one product line for different applications.

Handling Nets and Bags

Now that the difference between these two finger sizes has been clarified, let’s turn our attention to the GorillaFingers. Let’s consider the Gorilla – a large, strong grip that can carry more than normal human hands. For example, this is how a GorillaFinger would handle a bag of apples: by wrapping a single hand around it.

In our video, you can see how the robotic fingers wrap around the bag and more: the fingers tend to push individual apples, oranges, potatoes and onions up and stick to the packaging and netting. Combine multiple fingers with a centric gripper and you have a tool that is perfect for nets ranging in size from 1 kg to 3.5 kg, for example. Of course, the number of fingers varies depending on the application. While 1 kg can easily be handled by 3 GorillaFingers, a package of 3.5 kg is best handled by 5 GorillaFingers.

Bags and Nets of goods

Two prominent examples of the applications we have developed together with our customers:

- Potatonet of 2.5 kg

- Bag of apples of 2 kg

Handling heavy and large Fruits and Vegetables

Not only netted goods but also heavy goods are perfect for the GorillaFingers. Let’s take a look on goods that previosly have been concidered custom applications:

- Pineapples

- Califlowers

- Melons

- Dough

- And even Shoes

All relatively large products can be handled by the large robot fingers. Note that the pressure must be adjusted to the specific application. Higher payloads require higher pressure on the fingers, while more delicate goods may require lower pressure and more fingers to compensate for the weight. To ensure optimum service life and gripping force, we recommend a pressure of 1.2 to 1.5 bar.

To ensure stability over the entire service life, we therefore test our GorillaFingers for 10 million cycles at 1.3 bar pressure.

Custom applications will become standard in the future!

As you can see, we love working with our customers to develop the perfect SoftGripper for the job. This time it was the GorillaFinger used in a SoftActuator setup. However, this is not the last step in this line of robotic grippers. The next step is the fully FDA-approved GorillaFinger SoftGripper with the hygienic design you’ve come to expect from the SoftGripper product line.

Come to us with your project requirements and we will be able to accommodate your needs as well. This way you can join in, get a customized gripper and set standards in robotic product handling!

Contact

We are happy to get in touch with you! Let’s have a quick talk and find out how to automate your application. Our engineers will validate your application and provide you with test material in form of videos pictures and whitepapers: