What is the role of automation in modern bakeries?

Application

Industrial automation in bakeries must be handled case by case. There are multiple factors that influence how to approach automation. The size of the company is a relevant factor.

We can split this one topic into 3 subtopics: Automation in large bakeries, in middle-sized bakeries and in small ones.

We will be focusing on the products to be handled in the process. Although there are a number of different products that can be handled, we will focus mostly on bread and dough applications. This leaves chocolates, cakes and sweets to be fully discovered in a separate article.

We already have published a first application using SoftGrippers and SoftActuators on our website, so if you are looking forhandling raw dough and need some videos, make sure to visit this subpage to get some additional material.

Regarding more general view on the topic and how to choose a gripper for dough AND bread picking applications, this whitepaper will be a good overview to start with.

Structure of the industry

- Big companies go for fully automated processes and try to optimize processes to increase throughput. Scara and delta robots are usually a standard and high-speed pick&place and pick&package applications are performed with low downtimes. This means a high standardization of products and processes

- Medium-sized companies go for automation of easy tasks or subprocesses that are performed manually. High-speed delta robots are mixed with collaboration setups. Sometimes a production line is used for multiple bakery products. Versatility starts to play more of a role. Sometimes pick speeds are not as important and cobots start to be seen

- Small-sized companies go for simplicity of use, cobots and simplicity of use and reprogramming

Large companies

Large companies have integrators or internal teams working on making processes as efficient as possible. With the right capital whole production lines can be recreated using robotics, automated picking and placing of produce and other processes like cutting, folding, baking and fully automated quality control.

A good example is a whole baking street from dough preparation to packing of single pretzels into bags. A whole automated production line is built by a team of engineers where every detail must fit and be maintainable in runtime and debuggable with only short stops of production. After all time is money. These projects can take up from 3 month to more than one year. This includes an investment in capital where return of investment (ROI) may take multiple years, thus only viable to larger companies. This production lines are oftentimes preassembled by specialized integrators like Abendschön in a separate building and later on disassembled and transported to the actual space of use.

These machines produce standard goods and are especially difficult to reconfigure to a different product line. Using delta or scara robots, dough, raw buns and backed bread loafs is placed from and on trays or even into crates in packaging lines.

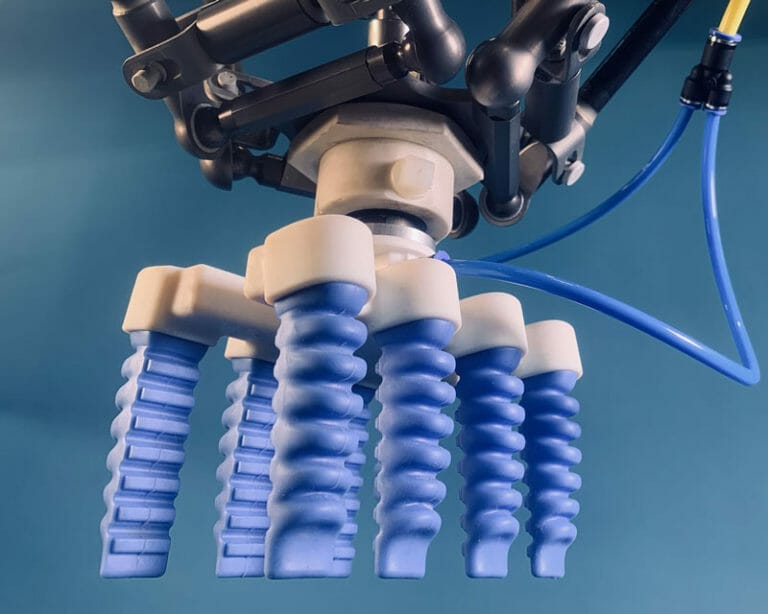

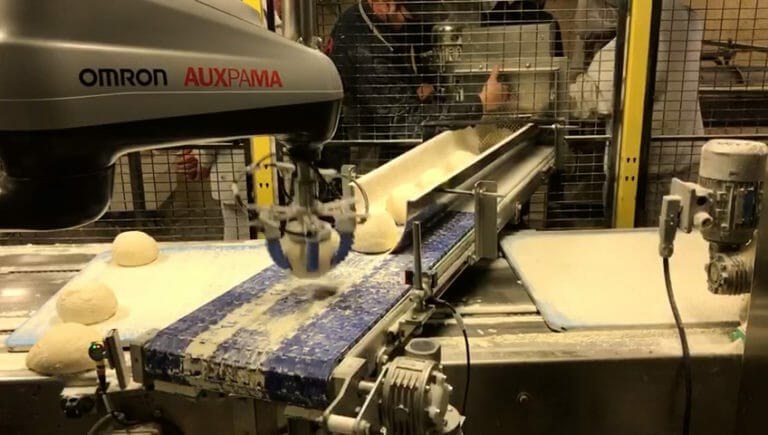

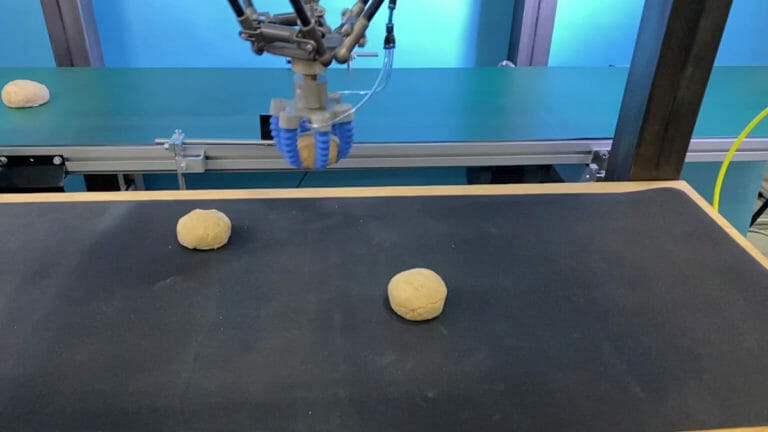

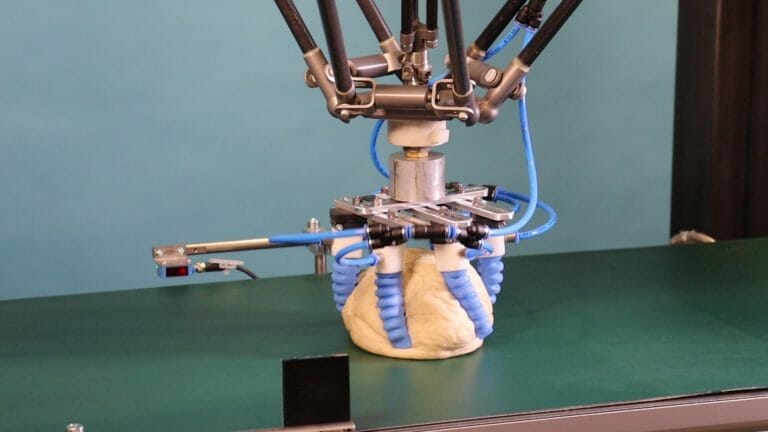

Our gripper system helps in high-speed setups to handle bread safely and with precise pick and release. A specialized production line that is trimmed for speed requires a gripper fit for the task. SoftGripping developed a doughball gripper that was developed together with ABI to handle dough without leaving gripper marks and to have perfect shape for doughballs handled in this setup. A SoftGripper is made from FDA compliant materials. Fingers from special silicones and gripper bases in a special process. Best of all: We specialize in rapid prototyping and manufacturing for FDA compliant applications. This means that grippers can be custom made to exactly fit the shape of your product. All without having to build the gripper base from multiple parts. This reduces possible unhygienic spaces drastically!

A bonus: The gripper can be washed with standard solutions used to clean and maintain the setup. Should you use a dishwasher for the gripper, we recommend a simple tool changer to make the life of the workers easier and reduce the amount of tools used on the factory ground.

Large companies have integrators or internal teams working on making processes as efficient as possible. With the right capital whole production lines can be recreated using robotics, automated picking and placing of produce and other processes like cutting, folding, baking and fully automated quality control.

A good example is a whole baking street from dough preparation to packing of single pretzels into bags. A whole automated production line is built by a team of engineers where every detail must fit and be maintainable in runtime and debuggable with only short stops of production. After all time is money. These projects can take up from 3 month to more than one year. This includes an investment in capital where return of investment (ROI) may take multiple years, thus only viable to larger companies. This production lines are oftentimes preassembled by specialized integrators like Abendschön in a separate building and later on disassembled and transported to the actual space of use.

These machines produce standard goods and are especially difficult to reconfigure to a different product line. Using delta or scara robots, dough, raw buns and backed bread loafs is placed from and on trays or even into crates in packaging lines.

Our gripper system helps in high-speed setups to handle bread safely and with precise pick and release. A specialized production line that is trimmed for speed requires a gripper fit for the task. SoftGripping developed a doughball gripper that was developed together with ABI to handle dough without leaving gripper marks and to have perfect shape for doughballs handled in this setup. A SoftGripper is made from FDA compliant materials. Fingers from special silicones and gripper bases in a special process. Best of all: We specialize in rapid prototyping and manufacturing for FDA compliant applications. This means that grippers can be custom made to exactly fit the shape of your product. All without having to build the gripper base from multiple parts. This reduces possible unhygienic spaces drastically!

A bonus: The gripper can be washed with standard solutions used to clean and maintain the setup. Should you use a dishwasher for the gripper, we recommend a simple tool changer to make the life of the workers easier and reduce the amount of tools used on the factory ground.

Middle sized companies

Middle sized companies may work with integrators, but the size of the lines to automate are smaller. Single stations are oftentimes a good target. The easier to automate – the better. You cannot find people for easy tasks: a perfect target for automation! Besides working with integrators and purchasing prebuilt system solutions that require changes in the work process and only automate one workstation at a time, own interaction efforts will be required to integrate systems, test them, and save costs wherever possible.

A second way to drastically save costs is using cobot setups that can be used in more than one way. Modern robotics enables programming using a graphical interface so giving the workforce a new tool that they can actually work with can be done after a short seminar. Our partners at Willich help companies discover robotic applications and train users to program tasks. Applications like this need universal gripper: one single tool to pick up multiple types and sizes of bread.

We tested out grippers for multiple applications:

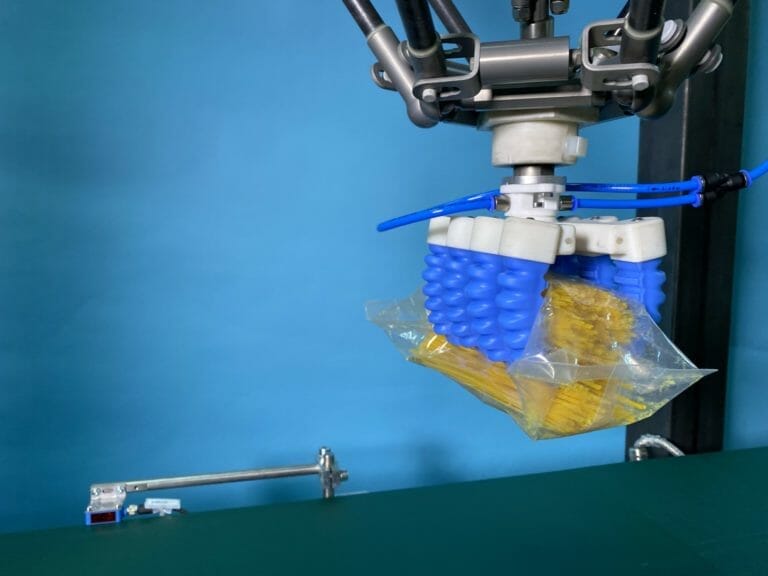

Handling bagged bakery goods like packed and cut bread, multiple buns in one bag, plastic crates with sweets, cookie rolls. In this test a bigger gripper was favorable. Not the weight of products, but the size was the main factor. Bread only weights only around 250g to 400g. Even bigger lumps of dough used for pizza production or as starting material for buns only go so far as 500g or 600g but yield a final product that can reach up to 300 mm in length. This requires a long gripper. We used an 8 finger parallel one.

The fingers grip around the package and adapt to the shape, so even if the package is not exactly prolonged but has a rather round shape, a safe pick can be performed.

Moving forward to bin picking or single product applications like tray packing developed by APEX motion for bakeries, a big gripper might be a little problematic. Not only is an 8-finger gripper more expensive in acquisition and maintenance because fingers must be changed out every 10 million cycles, but also in the size.

A smaller gripper is better to get into tight places and achieve a denser packing on trays. Here, we suggest a 4 finger centric gripper that was great for buns. The pressure setting on buns is not as important. Between 0.6 bar and 1.1 bar the difference was not noticeable, the crust on most buns is hard enough to withstand every setting. For raisin rolls on the other hand we suggest starting with a lower pressure settings to prevent squishing. Sometimes, like in this case less pressure is better and give a more secure grip, after all you would not pick up a roll using your hand with full force. All in all, with SoftGrippers it helps thinking about the gripping process like you would do it with your own hands! Just imagine having a couple more (or less) fingers. Coming from metal- or woodworking, the second option might be already the case.

Small companies

Small businesses can profit from robotic stations in multiple ways. Our company is based in Germany. Typically, finding young people who are willing to start a carrier at a bakery is a hard task. Not everyone is made to start a shift at early in the morning getting only a small loan in return. A great percentage of people finishing school are pursuing higher education. To ease the need for new workforce and making the field more attractive, many studies have been made to outfit small bakeries with robotic systems single stages of baking. E.g. placing dough in baking molds in the morning to make sure bread is ready before opening the store. A subdivision can be made between bakeries and the restaurant business. First robots were used as servants. Not only as part of a vending machine that already existed in the early 1880s, but as a real alternative for carrying dishes to the tables. Now, companies like Misorobotics explore the use of robotic arms in kitchens.

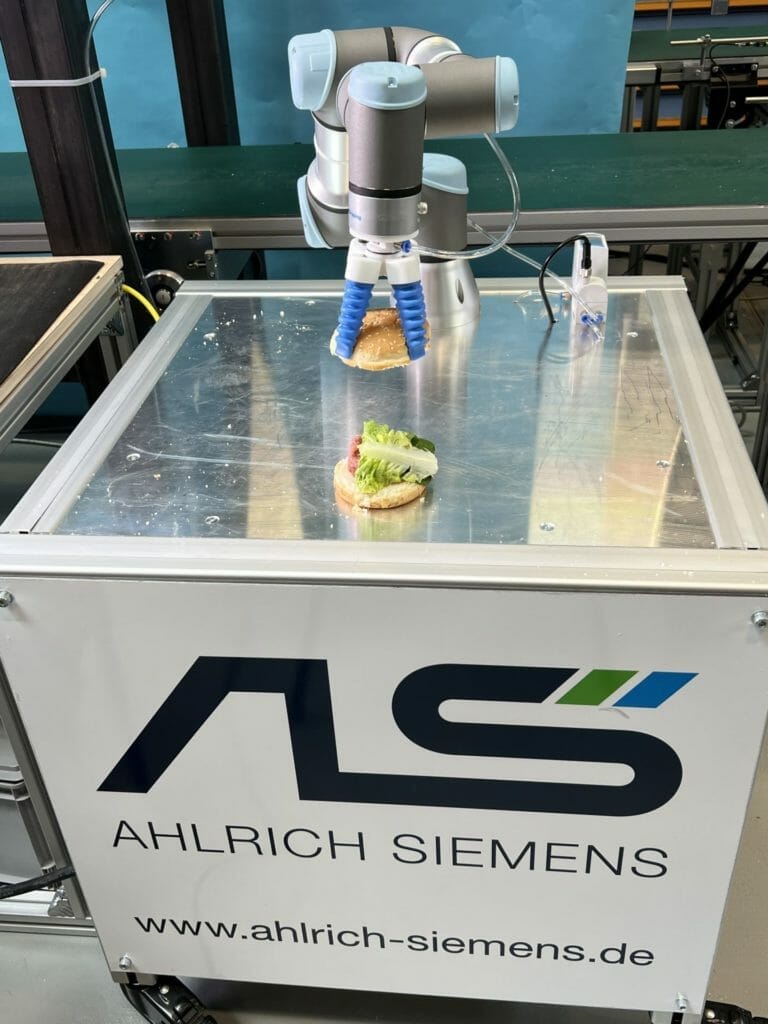

But let’s focus on the versatility of handling bread in small bakery shops: Of course, a cobot is best suited for those applications. Otherwise, the safety requirements to meet are just out of reach. Make sure the cobot can be used in food applications. Not all cobots are foodsafe, main aspect being the joint grease used and the many unhygienic spaces and materials used! So a warning ahead to all of you wanting to have a robot in kitchen or bakery setting. Next, a gripper that can pick up everything you need to handle is important. We cannot stress this enough: Choosing the right tool for the task is more important than any other aspect that can come to your mind! Make sure to decide what gripper to pick before you think about robots, pneumatics, robotcells or plattforms, or even full setups leaving the gripper to the rest. Guess what? If you cannot pick up all your produce, you won’t have the need for the rest. We get a number of desperate customers coming to us with everything already set up and a plethora of grippers used, but not a single one fit for the task. One application was the handling of burgers. Picking up the lower bun, a nice piece of burger patty with a molten piece of cheese on top, some lettuce that goes on top of the meat and finishing with the second piece of bread. A task that seems perfectly fine and easy for a human hand. This is what most common grippers are struggling with. A human hand in combination with eyesight has a lot of sensors figuring out the structure and give of every piece of produce. Bread is soft and light, lower and upper part have a different give to them: A robot clamp would require two different settings for pressure and positioning to pick the buns. A 4 finger SoftGripper finds it’s way around the bun. On the sides of the lower one and even on the sloped surface of the upper part. All with just one setting of pressure.

Next the patty: The meat might have the exact shape of the bun, but in our case the production went with a more fancy piece to handle. It is smaller than the bun, but higher. This would mean to have at least different settings on the gripper profile, but most of the time this would require a completely different tool and an automatic toolchanger between the handling steps.

Now for the really compliated part of the process of sandwich making. The salad leaf. What shape does it have? It does not have uniform shape and the give towards pressure highly depends on where and how you grip it. On top: Positioning might be tricky because it depends on how you place it on the patty. Here you need a gripper that finds its way around it as well. Last but not least, we finish with a bun on top of the lettuce. Here we neatly place it on top of the salad, but make sure that squishing it does not leave any marks on bread or salad. The gripper must be soft enough to respond to the environment. Our choice for a gripper was a 4 finger centric one with a 15° angle on the fingers. A slightly angled gripper helps with the variety of foods that can be gripped with a single gripper. A single gripper means a lower investment to get started with automation.

If you are not sure what gripper to get, a construction kit might be the best choice. The difference in price is low compared to e.g. a six finger gripper that is included with it, but you get more bases and adapters for several different robot models, a spacer and suction cup meaning you can try out more gripper models with one simple kit. This 4 minute video explains how it works.

All applications

Production line integration

High-speed pick and place

Most of the time there is more to it than just simple picking and placing. In dough handling for example a doughball might be preformed in a special conveyer belt setup and then needs to be set on a tray for baking. This tray is itself set on a second conveyer belt.

That is not all. Sorting, aligning products to have the same orientation or simple quality management to sort out products that don’t pass set thresholds is something we see on a daily basis. In alignment, we have to make sure to be precise but at the same time to be gentile to the product, even at higher speeds. Baffles on the side of the gripper can reduce shaking from acceleration and deacceleration in handling. Of course, good robot programming skills are useful, because simple adjustments to routing yield a smooth curve the robot arm is following. Spacers in the middle of the gripper on the other hand help with positioning of bread and buns in the claws of the gripper. This is to prevent slide up that can happen from shaking. It is especially important when the task is to position and realign raw buns for example.

Pick and package

Products that can be handled by a bakery SoftGripper

Frozen dough and buns

The standard mode of handling is in cold environments to not break the cooling chain. In that case, the settings of the pressure are not as important. Simply make sure that the size of the gripper more or less fits the size of produce. A slightly higher pressure is ok. Even with dough that you would consider to be soft, you would not get gripping marks. Even a slightly lower temperature makes dough a good material to handle. Make sure to have the dough frozen in testing your application. We did a bunch of tests on this topic for our customers. Some of those videos are presented above.

Room temperature dough

Bread and buns

Small cakes

Cakes come where fingers touch the surface or when a wrapper is covering the cake. In both cases the grippers can be used. Icing or chocolate on top will not be a problem, we know that from handling chocolates. But make sure to adjust pressure settings to 0.7-0.6 bar and use the surface area you have.

A special interest goes towards finger regidity and form stability needed to place cakes in plastic packaging or in so called machine tending applications. Using the 3 finger centric gripper, weights up to 150 g will not have an effect on the positioning even if the robot is moving goods upside down.

In food handling this might get especially interesting when products have to be flipped. But flipping sandwiches is a different topic to be discussed in a separate article, here is a link to the gripper used in this short test:

Sensitive products

Dough cookies and even chocolate-coated marshmallow treats, German “Schokokuss” are viable applications. Usually, it is best to analyse your product to see where the optimal gripping surface will be. In the second product for example, it will be the base made from hard waffle. But that is not always an option. 4 fingers using 0.5-0.6 bar of pressure will make sure not to leave gripper marks on them. To adjust spacing of a gripper will make sure the curvature of the closed fingers is adjusted do maximize surface area. It starts to matter more the faster your application gets.

Packing and packaged products

Contact

We are happy to get in touch with you! Let’s have a quick talk and find out how to automate your application. Our engineers will validate your application and provide you with test material in form of videos pictures and whitepapers: