Revolutionizing Robotics: The Rise of SoftGrippers for High Speed Robots

Table of Contents

Revolutionizing Robotics: The Rise of SoftGrippers for High Speed Robots - A Blogpost

In recent years, there has been a significant shift in the automation industries towards the development of automated robotics and solutions. Automated solutions have revolutionized the way businesses operate, and automation services have become an integral part of the modern manufacturing process. One of the key components of this automation revolution is the rise of soft grippers for high-speed robots. Soft grippers are a new type of robotic end-effector that has the ability to handle delicate and complex tasks with ease and speed. In this blogpost, we will discuss the benefits of soft grippers, how they are changing the automation industries, and why they are a critical component of modern automated solutions.

Introduction

Definition of SoftGrippers

SoftGrippers, also known as soft robotic grippers, are a type of robotic end-effector that is designed to handle delicate or sensitive objects in a gentle and safe manner. Unlike traditional robotic grippers that use rigid jaws to grip and manipulate objects, SoftGrippers use a soft and flexible material that can conform to the shape of the object being grasped. This makes them ideal for handling delicate and fragile objects, such as food items, without causing damage. If you want to know more about all types of grippers first: Check out our Comprehensive Guide on Grippers!

The Importance of SoftGrippers in the Future of Robotics

As robotics technology continues to advance, there is a growing demand for more flexible and versatile robotic grippers. SoftGrippers are quickly becoming an essential tool in the field of robotics, especially in applications where precision and safety are a top priority. Whether it’s in the handling of delicate food items or the manipulation of sensitive materials, SoftGrippers offer a unique solution that is both effective and efficient.

The Rise of SoftGrippers for High Speed Robots

The use of SoftGrippers in high speed robots is on the rise, and for good reason. With their ability to handle delicate objects without causing damage, SoftGrippers have proven to be an ideal solution for applications that require high speeds and precise movements. By combining the benefits of SoftGrippers with the speed and efficiency of high speed robots, engineers and manufacturers can achieve a level of automation that was previously unattainable. This is why the use of SoftGrippers in high speed robots is rapidly becoming an industry standard, and why they are poised to play an important role in the future of robotics and factory automation.

The Advantages of SoftGrippers in Robotics

Flexible Gripping

One of the key advantages of SoftGrippers is their ability to grip objects in a flexible and adaptable manner. Unlike traditional robotic grippers, which use rigid jaws to grip objects, SoftGrippers are able to conform to the shape of the object being grasped. This makes them ideal for handling delicate and fragile objects, such as fruits and vegetables, without causing damage.

Safe Food Handling

SoftGrippers are also ideal for handling food items, such as fish, meat, and sweets, in a safe and hygienic manner. The soft and flexible material used in SoftGrippers prevents contamination of the food items, ensuring that they are safe for consumption. Additionally, the soft material also helps to reduce the risk of injury to workers handling the food items, making it a safer working environment.

Improved Productivity

The use of SoftGrippers in robotics has also been shown to improve productivity in various industries. For example, in the food industry, the use of SoftGrippers has allowed for the automation of tasks such as packing and sorting, freeing up workers to perform other tasks. This has resulted in increased efficiency and a reduction in the amount of time required to complete a task.

Increased Efficiency

Finally, the use of SoftGrippers in robotics has been shown to increase efficiency. By allowing robots to handle delicate and fragile objects with ease, SoftGrippers have eliminated the need for manual handling, reducing the risk of damage to the objects and freeing up workers to perform other tasks. Additionally, the soft and flexible material used in SoftGrippers also reduces the time required to grip and manipulate objects, further increasing efficiency. This does not only apply to high speed automated solutions, but for cobot applications as well.

Applications of SoftGrippers in High Speed Robots

Fish Handling

In the fish handling industry, SoftGrippers have proven to be a game-changer for high speed robots. The soft and flexible material used in SoftGrippers allows for gentle and effective handling of fish, reducing the risk of damage and ensuring that the fish remain in optimal condition. The use of SoftGrippers has also eliminated the need for manual handling, freeing up workers to perform other tasks and increasing efficiency.

Fish Handling | Gripper Type | Number of Fingers |

|---|---|---|

Salmon Fillet | Parallel Gripper | 4 |

Tuna Steak | Centric Gripper | 4 |

Trout Whole | Parallel Gripper | 6 |

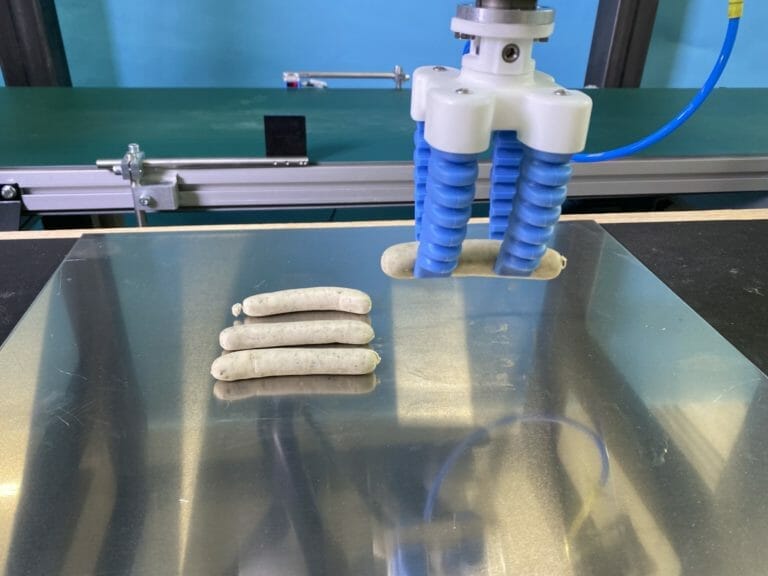

Protein Handling

In the meat handling industry, SoftGrippers have been used to automate the handling of protein products, such as chicken and beef. The soft and flexible material used in SoftGrippers allows for gentle handling of the meat, reducing the risk of damage and ensuring that the product remains in optimal condition. The use of SoftGrippers has also eliminated the need for manual handling, freeing up workers to perform other tasks and increasing efficiency. We strongly recommend to check out the whitepaper we made regarding this topic!

Protein Handling | Gripper Type | Number of Fingers |

|---|---|---|

Chicken Drumstick | Parallel Gripper | 4 |

Beef Ribs | GorillaFinger Centric Gripper | 4 |

Trout Whole | Parallel Gripper | 6 |

Sweets Handling

In the sweets handling industry, SoftGrippers have been used to automate the handling of delicate sweets, such as chocolates and candies. The soft and flexible material used in SoftGrippers allows for gentle handling of the sweets, reducing the risk of damage and ensuring that the product remains in optimal condition. The use of SoftGrippers has also eliminated the need for manual handling, freeing up workers to perform other tasks and increasing efficiency.

Sweets Handling | Gripper Type | Number of Fingers |

|---|---|---|

Chocolate Bars | Parallel Gripper | 4 |

Gummy Bears | Parallel Gripper | 2 |

Muffin | Centric Gripper | 3 |

Other Examples

SoftGrippers have also been used in other applications, such as handling delicate electronic components, medical equipment, and various other objects. The soft and flexible material used in SoftGrippers allows for gentle handling of delicate objects, reducing the risk of damage and increasing efficiency.

Other Applications | Gripper Type | Number of Fingers |

|---|---|---|

Electronic Circuit Boards | Centric Gripper | 4 |

Medical Syringes | Parallel Gripper | 2 |

Glass Vials | Parallel Gripper | 4 |

The Benefits of Using SoftGrippers for Food Handling in High Speed Robots

Reduced Waste

One of the lesser known benefits of using SoftGrippers in high speed robots is the reduction in food waste. SoftGrippers are equipped with advanced technologies that allow for a gentler grip, reducing the risk of crushing or damaging delicate food products during the handling process. This results in a reduction in food waste and a significant increase in overall efficiency.

Improved Food Quality

Another advantage of using SoftGrippers in food handling is the improved quality of the food products themselves. Traditional grippers can cause bruising and damage to delicate foods, which can negatively impact the overall quality and appearance of the product. SoftGrippers, on the other hand, are designed to handle delicate food products with care, resulting in products that are of a higher quality and more visually appealing to consumers.

Enhanced Safety Standards

Finally, the use of SoftGrippers in high speed robots also results in enhanced safety standards. SoftGrippers are equipped with safety features that help to prevent contamination of food products during the handling process. This not only ensures that food products are safe for consumption, but also helps to maintain high levels of hygiene and cleanliness in food production facilities. By using SoftGrippers in food handling, companies can demonstrate their commitment to food safety and quality, which is a major concern for consumers today.

Disadvantages of automation in agriculture

Automation in agriculture, although promising in terms of increasing efficiency and productivity, is not without its disadvantages. Firstly, the cost of implementing automated systems and equipment can be prohibitively expensive for small-scale farmers and can lead to a consolidation of the industry, with larger corporations having an advantage over smaller operations. Additionally, there may be job losses as manual labor is replaced by machines, potentially leading to a decline in rural communities. Furthermore, relying solely on technology can also increase the risk of crop failures as a result of mechanical malfunctions or software errors. Lastly, there is also a risk of over-reliance on automated systems, which can lead to a lack of knowledge and understanding of traditional farming practices and the loss of important skills and techniques that have been passed down for generations.

Enhanced Safety Standards

Finally, the use of SoftGrippers in high speed robots also results in enhanced safety standards. SoftGrippers are equipped with safety features that help to prevent contamination of food products during the handling process. This not only ensures that food products are safe for consumption, but also helps to maintain high levels of hygiene and cleanliness in food production facilities. By using SoftGrippers in food handling, companies can demonstrate their commitment to food safety and quality, which is a major concern for consumers today.

Conclusion

Well, SoftGrippers have revolutionized the field of robotics in factory automation, particularly in the handling of delicate and sensitive objects such as food products. SoftGrippers offer a number of key advantages over traditional grippers, including increased flexibility, improved safety, enhanced efficiency, and reduced waste.

The use of SoftGrippers in high speed robots has led to improved food quality, enhanced safety standards, and reduced food waste. The advanced technologies used in the design and construction of SoftGrippers allow for a gentler grip on delicate food products, resulting in products that are of a higher quality and more visually appealing to consumers.

in Factory Automation SoftGrippers represent a major shift in the field of automated robotics, and are poised to play an increasingly important role in the future of factory automation. The benefits of using SoftGrippers in high speed robots are clear, and their use is becoming more widespread as companies seek to improve the efficiency and quality of their operations.

As the demand for high speed robots in factory automation continues to grow, it is likely that we will see further advancements in the design and development of SoftGrippers. In particular, there is a growing need for SoftGrippers that are capable of handling an even wider range of objects, from delicate food products to heavy industrial components.

In conclusion, the rise of SoftGrippers in factory automation represents a major milestone in the field of robotics, and is set to play an increasingly important role in the future of this rapidly evolving industry. Whether you are a manufacturer looking to improve the efficiency of your operations, or an engineer looking to stay up-to-date with the latest advancements in robotics, it is worth taking the time to explore the many benefits of SoftGrippers and how they can help you achieve your goals.

Your Next Steps

As an engineer looking to incorporate SoftGrippers into your factory automation setup, there are a few important steps you can take to ensure you choose the right gripper for your needs. Here’s what you need to do:

- Research: Start by visiting our Solutions page and researching the different types of SoftGrippers available on the market. Read through the white papers of different setups already used in the industry to get a better understanding of what’s available and what might be a good fit for your needs.

- Consult with Experts: Contact our team of experienced engineers to discuss your specific needs and get personalized recommendations. Our experts have extensive knowledge and experience with SoftGrippers and can help you find the right solution for your factory automation setup.

- Schedule a Meeting: Schedule a meeting with our engineers to discuss your specific requirements in detail. This will give you the opportunity to see the SoftGrippers in action and get a hands-on feel for how they work.

- Choose the Right Gripper: Based on your research, consultations with our experts, and hands-on experience with the SoftGrippers, you can make an informed decision on the right gripper for your factory automation setup. Whether you’re looking to handle fish, meat, sweets, or any other type of object, our team is here to help you find the right automation solution for your needs.

By following these steps, you can ensure that you choose the right SoftGripper for your factory automation setup and start experiencing the many benefits that come with using these innovative grippers. So why wait? Get started today and take the first step towards revolutionizing your robotics setup with SoftGrippers.

Further advice!

When it comes to incorporating SoftGrippers into your factory automation setup, it’s important to remember that there’s no one-size-fits-all solution. Every factory is unique and has its own specific needs, so it’s crucial to take the time to research and consult with experts to find the right solution for you.

Here’s some witty advice to help you along the way: “The greatest glory in living lies not in never falling, but in rising every time we fall.” -Nelson Mandela

Just like in life, you may encounter obstacles and challenges when incorporating SoftGrippers into your factory automation setup. But don’t let that discourage you. Instead, take it as an opportunity to learn and grow, and continue pushing forward towards your goal of revolutionizing your robotics setup with SoftGrippers. And remember, our team of experts is here to help you every step of the way!

Contact

We are happy to get in touch with you! Let’s have a quick talk and find out how to automate your application. Our engineers will validate your application and provide you with test material in form of videos pictures and whitepapers: