Robotic grippers for protein handling: Steak, poultry and sausages

Application

Since the pandemic hit the protein industry and the food processing industry in general, we have seen the trend of large manufacturers of consumer protein products that used a lot of labor turning to forward-looking solutions. Not only for hygienic reasons or to save on personnel, but also because labor was hard to find in this area, especially not in the quantities that companies like Tönnies need to function. The task of automating entire production lines went to integrators. That’s not to say that automated production lines for protein processing, meat preparation or sandwich making didn’t exist before; solutions for cutting and processing chicken were already on the market, but new developments in robotics, peripherals and end-of-arm tooling have made automation solutions more accessible at any size company in food manufacturing and even for niche applications. In this article, we discuss the technological advances in protein processing and highlight some of the applications we have done with our partners in the industry. All of this is to show you what to look for when developing an automated protein processing line.

Industrial standards in robotic protein processing: Food safety regulations

First, we need to talk about hygiene concepts in raw meat processing. The exact food safety guidelines vary from country to country, but one thing is undeniable: protein processing is a highly regulated area, and hygienic conditions are key to the operation of any plant. Food safety quality assurance will be with you every step of the way. Special attention is paid to hygienic design. Newer Delta robots designed for use in food environments are made entirely of stainless steel and can be cleaned with pressurized water and detergents without damaging the electronics. At the same time, the design ensures that no product parts get caught and create unsanitary spaces. Conveyor belts follow a slightly different logic. First of all, in food production, the belts are perforated and therefore easier to clean with pressurized water. The blue color is for safety, as the products are usually not blue, so the equipment can be easily distinguished from the goods. Other food contact components, such as our fingers, follow the same color logic. In addition, our SoftGripping product line follows a hygienic design with beveled surfaces, special seals and screws. This allows product residues and cleaning agents to roll off easily, leaving behind clean and hygienic surfaces.

For us as a gripper manufacturer, one thing became clear: Most automation systems inthe food industry with conveyors, industrial robots, cameras, automated packaging equipment and delivery stations differ slightly from application to application. They are often built first and the most important piece of the puzzle is only solved at the last moment: the robot gripper! The part that comes into contact with the food must simply be considered first. Food contact means that the shape of the gripper must be adapted to the product in question. A gripper that is optimized for the protein being handled means a more precise grip, less variation in picking and placement, and most importantly, less chance of handling errors! For this reason, we need to look at the typical challenges of handling protein and know what to look for, such as: Weight distribution, general shape, containers to pick up and put down. All with the aim of making the process as fast as possible and, above all, reliable!

Alternatives to suction cups in pick&place of Protein

Usage of soft grippers in Protein picking and packaging

Pick and place

The first application that comes to mind is simply removing protein from the production line and placing it in boxes or trays for packaging. This step could be done after a line where the meat is cut. Here, the cutting of protein can be done either by factory workers or in an automated manner. What struck us here is that simply separating pieces of meat could save a lot of money on 3D vision and processing that would be required for the robot to pick individual pieces of meat. By the way, when we talk about pick-and-place applications, we’re talking about fast robots like Delta or Scara robots, and usually a production line with more than a few robots for a task.

Pick and package

Picking and packing protein could be similar to a pick and place application, but if pick and place is used to align pieces or transfer them from one conveyor to another, for example, pick and pack means having a tray, bag, or similar container in which to place chicken wings or sausages, for example. One application besides tray packing was to pack fried chicken wings in paper bags that were then dispensed and opened, another was to place sausages in fairly narrow containers. Be sure to investigate the space requirements for the grab-and-go operation. Some containers can be extremely narrow and the grippers should not be dipping deep inside to place the product. Instead, it’s a good idea to clear the gripper a few inches into the narrow package or even slightly above. Using a spacer between the gripper fingers will help with stability and alignment of protein goods, ensuring controlled release and placement in packing machines.

Sorting applications

Sorting isn’t just about making sure pieces are properly aligned for the next task or separating different cuts into multiple product streams. The simplest task we encountered was making sure the pieces were assembled into dishes of a certain weight. Protein, like pork cuts always varies in size and weight, but what the end customer sees is a packaged product of, say, 500 g! So the pieces of protein must weigh at least 500 g to ensure that the customer gets what he paid for. But the extra weight of the packaged goods is something that could have been distributed differently among the boxes. In this case, each piece of meat is weighed and given an ID. Pieces that meet the required packaging weight are put together by robotic fingers in the primary packaging process. This ensures efficient product distribution.

Protein gripper as part of an actuator

Multistep product preparation

Primary packaging lines vs secondary packaging lines

Robotic protein gripping with softgripping, what to look for?

Our Examples for robotic protein handling and protein packaging machines

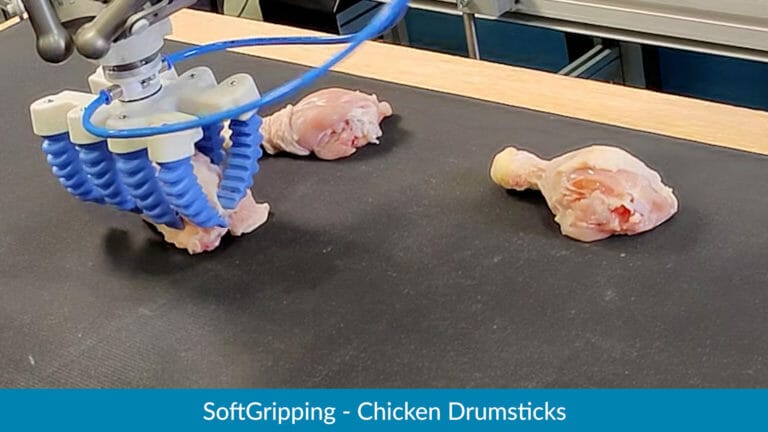

Chicken drumsticks

Let’s start with one of the most well-known applications in automated protein processing: picking up and placing chicken legs. At first glance it seems simple, but for conventional grippers the asymmetry and chicken skin would cause many problems. Gripping around the meat is important here to maintain balance. A slight tendency to grip near the center mass can help with stabilization. Most importantly, pressure on the fingers must be adjusted to ensure the chicken skin stays in place during the pick-and-place cycle. What makes the task easier compared to other cuts of protein is the bone inside the leg, where the gripper can hold the piece of protein well.

Recommended gripper setup for robotic chicken drumstick handling

Automated handling of filets and tenderloins

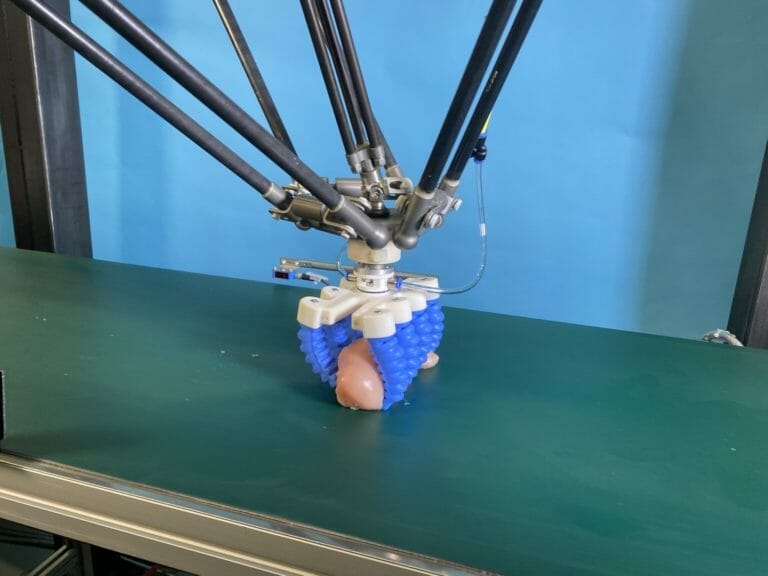

We have chosen the chicken breast fillet as a good example of meat cuts to be processed automatically. Of course, the results may vary depending on the tenderness of the protein and the shape of the cut and thus the weight distribution in the piece. These are important parameters when switching from chicken to beef or pork. In the present case, rather large pieces with a good height are handled so that a human or robotic hand can easily pick them up. Flatter and wider pieces, on the other hand, are more difficult to handle. Here, up to a certain size, it can be useful to press the pieces against a spacer instead of letting them slide into the gripper fingers. In addition to the size of the pieces and the cooling condition, you should also take a close look at the marinade used.

Recommended gripper setup for handling filets

Robotic meatball handling

Recommended robotic setup for meatball handling

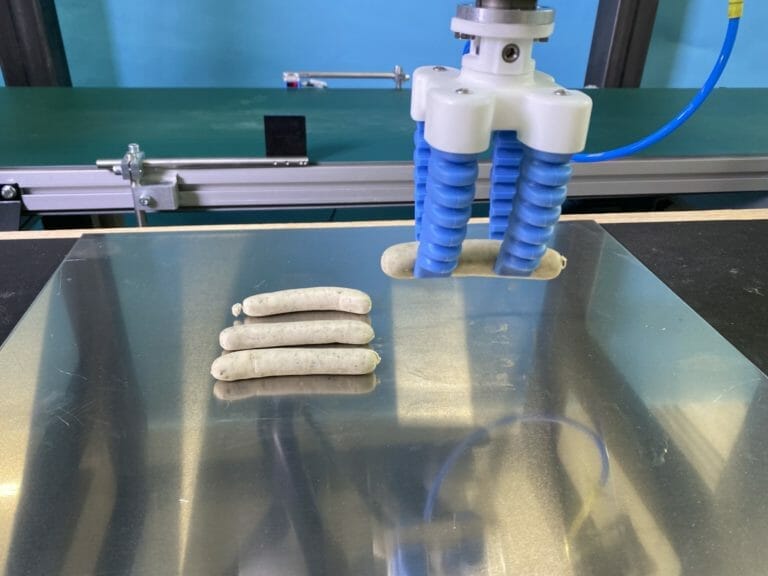

Sausage primary packaging machines

The perfect gripper for handling sausages

Cobot burger preparation

- 1. Use multiple robots for specific tasks. This speeds up meal preparation, but requires a larger investment and, more importantly, more space in restaurants where space is a factor.

- 2. Use one robot with a tool change station and dedicated end-of-arm tools for specific tasks. This may seem beneficial at first glance, but an automated tool changer in a food preparation environment can lead to sanitation issues, and more importantly, changing tools between tasks is time-consuming and inefficient, even if the setup is on display to the delight of customers.

- 3. Develop an end-of-arm tool that can handle all required tasks. This can be done by attaching multiple tools to the robot in an EoAT or a flexible gripper that can handle all parts. This is the way of SoftGripping! Our fingers gently wrap around buns, patties and even lettuce leaves. When you pick up a stack of these products and place them under a condiment dispenser (ketchup, mayonaise, etc.), you can be sure that all the pieces will be processed in one go.

Recommended automated setup for preparing burgers

Contact

We are happy to get in touch with you! Let’s have a quick talk and find out how to automate your application. Our engineers will validate your application and provide you with test material in form of videos pictures and whitepapers: