How Soft Grippers and Delta Robots are Transforming the Vegetable Processing Industry

Table of Contents

Vegetable handling and processing - A quick introduction

The handling of delicate vegetables such as salads and kale is a critical issue in the field of agriculture and food processing. In order to address this challenge, we have conducted a study on the optimization and adjustment of soft grippers for vegetable handling. The results of our study demonstrate the feasibility and effectiveness of using soft grippers in handling a variety of delicate vegetables, including salads and kale.

For those who missed it, our previous study and accompanying white paper provide a comprehensive overview of our findings and the methodology used. In this article, we aim to further elaborate on the significance of our study and why the application of soft grippers in vegetable handling is so important.

Soft grippers are designed to handle delicate objects without causing any damage, making them an ideal solution for handling delicate vegetables. The use of soft grippers in vegetable handling can result in increased efficiency and reduced waste, as well as improved food safety and quality.

Introduction to vegetable processing and the role of automation

Vegetable processing is an important industry that involves the handling, preservation, and packaging of vegetables for distribution and consumption. With the increasing demand for high-quality, safe and affordable vegetables, the industry has embraced automation in recent years to improve efficiency, reduce waste and increase production capacity. In this blog post, we will be exploring the use of soft grippers and delta robots in modern vegetable processing factories and how they are revolutionizing the industry.

The use of soft grippers in vegetable processing

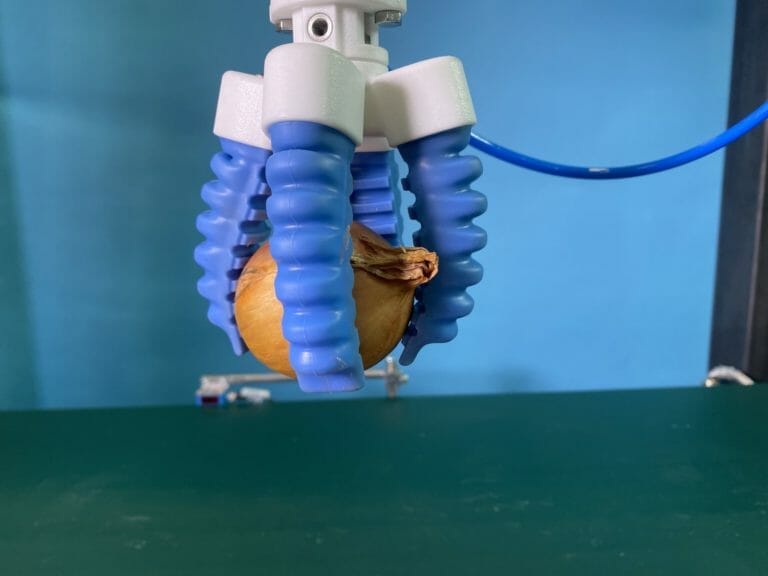

Soft grippers are a type of robotic end effector that are specifically designed to handle delicate and perishable goods, such as vegetables. Unlike traditional mechanical grippers that use a clamping mechanism, soft grippers are made of a flexible material, such as silicone, that can adapt to the shape of the object being picked up, without causing damage. This makes them ideal for handling delicate vegetables, such as strawberries or cherry tomatoes, that would otherwise be too fragile for mechanical grippers to pick up.

The combination of soft grippers and high speed delta robots

By combining soft grippers with high speed delta robots, modern vegetable processing factories are able to achieve a high level of automation in the handling and processing of vegetables. Delta robots are fast and precise robots that are able to move in three dimensions and can be equipped with soft grippers to handle delicate goods. This combination of technologies provides a high level of efficiency and accuracy in vegetable processing, reducing waste and increasing production capacity.

Benefits of using soft grippers and delta robots in vegetable processing

The use of soft grippers and delta robots in vegetable processing offers several benefits, including:

- Increased efficiency: By automating the handling and processing of vegetables, the use of soft grippers and delta robots can significantly increase the efficiency of the production process, reducing waste and increasing production capacity. This results in a faster and more streamlined process, allowing the factory to produce more vegetables in less time.

- Improved quality control: The use of delta robots equipped with soft grippers ensures that the handling of vegetables is consistent and accurate, reducing the risk of damage to the goods. This helps to maintain the quality of the vegetables and ensures that they reach the customer in the best possible condition.

- Enhanced food safety: The use of soft grippers and delta robots reduces the risk of contamination and ensures that the handling of vegetables is hygienic. This is important in the food industry where maintaining food safety is critical to protect consumers and ensure that the product meets regulatory requirements.

Disadvantages of automation in agriculture

Automation in agriculture, although promising in terms of increasing efficiency and productivity, is not without its disadvantages. Firstly, the cost of implementing automated systems and equipment can be prohibitively expensive for small-scale farmers and can lead to a consolidation of the industry, with larger corporations having an advantage over smaller operations. Additionally, there may be job losses as manual labor is replaced by machines, potentially leading to a decline in rural communities. Furthermore, relying solely on technology can also increase the risk of crop failures as a result of mechanical malfunctions or software errors. Lastly, there is also a risk of over-reliance on automated systems, which can lead to a lack of knowledge and understanding of traditional farming practices and the loss of important skills and techniques that have been passed down for generations.

Not all is lost - A counter perspective

However not all is lost, here is why:

The cost of automation can be high for small-scale farmers – This is true, but in the long-term, the increased efficiency and productivity brought about by automation can help small-scale farmers become more competitive and profitable, making the investment worthwhile.

Job losses – While automation may lead to a decline in manual labor jobs, it also creates new jobs in areas such as maintenance and repair of equipment, software development, and data analysis.

Risk of crop failures – While there is a risk of mechanical malfunctions or software errors, proper maintenance and monitoring can mitigate these risks. Additionally, the use of multiple redundant systems can provide a backup in case of a failure.

Over-reliance on technology – While it is important to maintain traditional farming practices and techniques, the use of technology can also enhance and improve these practices, leading to more sustainable and efficient farming operations.

In summary, while the disadvantages of automation in agriculture are worth considering, it is also important to consider the potential benefits and advantages that it can bring to the industry.

Quality control and food safety considerations

Quality control and food safety are essential considerations in any vegetable processing factory. The use of soft grippers and delta robots helps to maintain the quality of the vegetables and ensure that they are handled in a hygienic and safe manner. Regular maintenance and cleaning of the robots and grippers is important to ensure that they are functioning correctly and that there is no risk of contamination. It is also important to follow proper food safety procedures and regulations to ensure that the vegetables are processed and packaged in a safe and hygienic manner.

Conclusion and future outlook

The use of soft grippers and delta robots in modern vegetable processing factories is transforming the industry and providing a range of benefits, including increased efficiency, improved quality control and enhanced food safety. With continued advancements in technology, it is likely that we will see an even greater use of robotic automation in the vegetable processing industry in the future. The use of soft grippers and delta robots is just one example of how innovation is changing the face of this industry and helping to meet the increasing demand for high-quality, safe and affordable vegetables.

So how can your automated robotics setup profit from this development?

Well, first of all: Go ahead and read the whitepaper studies we have prepared for you:

- Get a solid grasp on the topic by starting with large, packed, and bagged vegetables.

- When facing a unique challenge, don’t be afraid to get creative with a custom gripper.

- Even the seemingly impossible is within reach, as our research demonstrates solutions for all types of vegetable handling.

Done reading? Great! Now it’s time to go ahead and book a meeting with our engineers to discuss your topic:

Contact

We are happy to get in touch with you! Let’s have a quick talk and find out how to automate your application. Our engineers will validate your application and provide you with test material in form of videos pictures and whitepapers: