Hygienic Gripper Design for 3 Important Robot Applications in the Food Processing Industry

Table of Contents

Introduction

In recent years, the food processing industry has seen a rapid increase in the use of robots to improve efficiency and productivity. However, the use of robots in food processing also presents unique challenges, particularly when it comes to maintaining hygiene standards. This is where the concept of hygienic soft gripper design comes into play. In this article, we will explore the definition of hygienic soft gripper design, its importance in the food processing industry, and the use of robots in this industry.

Definition of Hygienic Gripper Design

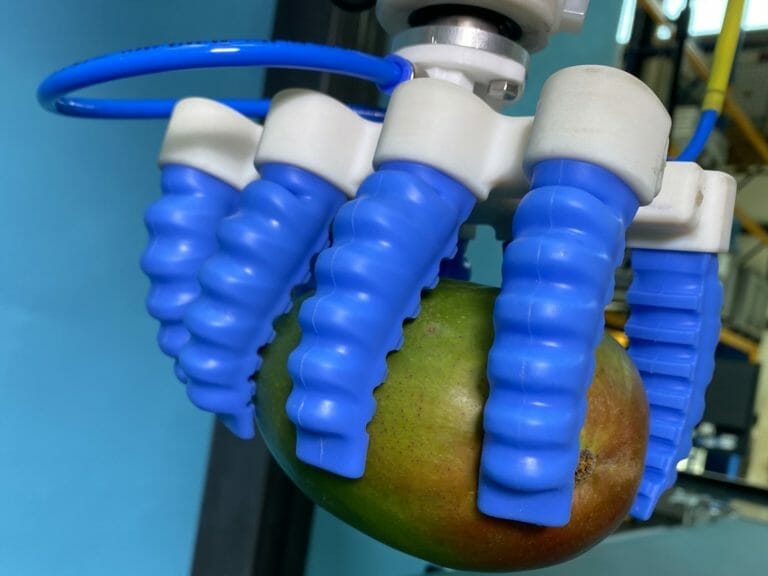

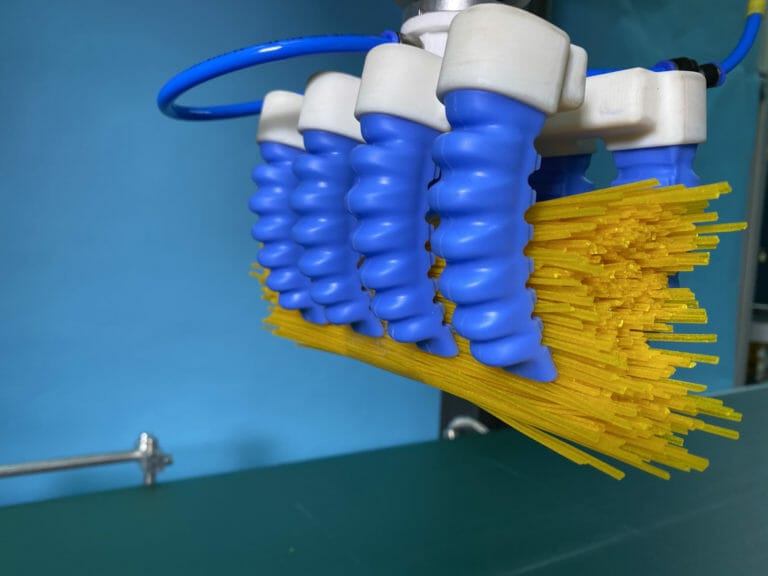

A gripper is a robotic end effector that is designed to mimic the grasping and holding capabilities of a human hand. It is typically made of soft materials, such as silicone or rubber, and is able to adapt to the shape and size of objects being gripped. Hygienic soft gripper design refers to the development of soft grippers that meet strict hygiene standards, particularly in the food processing industry. These grippers are designed to be easily cleaned and sanitized, and to minimize the risk of contamination.

The Importance of Hygiene in the Food Processing Industry

Maintaining high levels of hygiene is critical in the food processing industry to ensure the safety and quality of the products being produced. The use of robots in food processing presents unique challenges when it comes to maintaining hygiene standards. Traditional robotic end effectors, such as metal grippers, are difficult to clean and can harbor bacteria and other contaminants. This is where hygienic soft gripper design comes into play. By using soft, easy-to-clean materials, these grippers help to minimize the risk of contamination and ensure that the products being produced are safe for consumption.

The Use of Robots in the Food Processing Industry

The use of robots in the food processing industry has become increasingly common in recent years, driven by the need to improve efficiency and productivity. Robots can perform a wide range of tasks, including picking and placing products, packaging, and palletizing. However, the use of robots in this industry also presents unique challenges, particularly when it comes to maintaining hygiene standards. This is where hygienic soft gripper design can help. By using grippers that are designed to be easily cleaned and sanitized, robots can help to improve hygiene standards and ensure the safety and quality of the products being produced.

Challenges with Traditional Gripper Design in the Food Processing Industry

Traditional gripper designs, such as metal and hard plastic grippers, have been widely used in the food processing industry for many years. However, these grippers present several challenges in terms of hygiene and safety. One of the most significant challenges is the risk of contamination. Traditional grippers have small crevices and sharp edges that can trap food particles, leading to the growth of harmful bacteria and the risk of contamination.

Furthermore, cleaning traditional grippers can be a difficult and time-consuming process. The small crevices and tight spaces make it challenging to remove all traces of dirt and bacteria, which can result in inadequate cleaning and contamination of the food products. Additionally, some traditional grippers cannot withstand high-temperature washdowns, which are commonly used in the food processing industry to sanitize equipment.

Another challenge with traditional gripper designs is their limited versatility. These grippers are often designed for specific tasks and cannot be easily adapted to different shapes, sizes, and textures of food products. This limitation can slow down the production process, reduce efficiency, and increase the risk of contamination. Therefore, there is a need for a new type of gripper that is both hygienic and versatile for use in the food processing industry.

The new approach using soft gripper designs for superior hygenic designs

The new approach of using hygienic soft grippers in the food processing industry provides several advantages over traditional gripper designs. Firstly, the risk of contamination is significantly reduced as the soft grippers are made of materials that are easy to clean and do not have any hard-to-reach crevices where bacteria can accumulate. Secondly, the versatility of the soft grippers allows them to be used for a wide range of food products without the need for frequent reconfiguration. Additionally, the flexibility of the soft gripper fingers means that they can easily conform to the shape of the produce being handled, which results in a more secure grip, especially for delicate or irregularly shaped items. These advantages make hygienic soft grippers an attractive solution for the food processing industry, where maintaining high levels of hygiene and product quality are critical.

Materials Used in Hygienic Soft Gripper Design

When it comes to designing hygienic soft grippers for use in the food processing industry, the choice of materials is critical. The materials used must be food-safe, durable, and capable of withstanding frequent cleaning and sanitization. There are several materials commonly used in hygienic soft gripper design, including food-grade silicone, thermoplastic elastomer (TPE) such as polyurethane and rubbers. But there are different elements that are made from different materials first here is the difference in parts and materials:

Hygienic Elements

A SoftGripping Hygienic SoftGripper is made out of two elements: The base and the finger arrays.

Base

The base will be adapted to the shape of your object. While a circular object needs a centric base, a long object needs a parallel one.

We like to design a fully individual base for your task in shortest time. The angle of the fingers and the size of the base is specially made for your special requirements. Here hygienic 3D printing and mateirals are key.

Finger Arrays

To adapt to the dimensions and weight of your object, we use our finger arrays with different number of fingers. The arrays are easily mounted to the base with integrated air supply. Our pneumatically driven fingers are made of FDA-approved silicon rubber.

Food-grade silicones

Food-grade silicone is a popular material for soft gripper design due to its excellent resistance to heat and chemicals. It is a non-reactive material that does not leach harmful chemicals into food products. Additionally, silicone is flexible and durable, making it suitable for use in a wide range of food processing applications.

Thermoplastic elastomers

Thermoplastic elastomers (TPE) are another material commonly used in hygienic soft gripper design. TPEs are a type of rubber-like material that can be molded into different shapes and sizes. They are also resistant to heat and chemicals and can withstand frequent cleaning and sanitization. Furthermore, TPEs have good grip properties, making them ideal for handling a wide range of food products. Polyurethane is a versatile material that is used in a variety of industries, including the food processing industry. It is resistant to abrasion, chemicals, and high temperatures, making it suitable for use in harsh environments. Additionally, polyurethane is a flexible material that can be molded into different shapes and sizes, making it suitable for use in soft gripper design.

Food-grade rubbers for soft grippers

Food-grade rubbers are an essential component in the design of hygienic soft gripper fingers. These rubbers are specifically formulated to meet the strict requirements of the food processing industry, ensuring that they do not contaminate food products or affect their taste and quality. They are also durable, resistant to wear and tear and provide a strong grip, making them ideal for repeated use in industrial applications. Additionally, food-grade rubbers come in various grades, allowing for flexibility in grip strength and adaptability to different types of produce. Overall, the use of food-grade rubbers in soft gripper design is crucial for maintaining hygienic standards and ensuring safe and efficient food handling.

Food-grade base materials

One potential solution to the challenges of designing hygienic soft grippers for the food processing industry is to use FDA-approved selective laser sintering (SLS) materials to create custom bases that are tailored to the shape of the produce being handled. SLS allows for the creation of complex geometries and intricate shapes that are difficult to achieve with traditional manufacturing methods, and the use of FDA-approved materials ensures that the grippers are safe for use in food handling applications. By creating bases that are precisely shaped to the produce being handled, the grippers can provide a more secure and gentle grip, reducing the risk of damage or contamination.

Material selection is critical

In conclusion, the choice of materials used in hygienic soft gripper design is critical to ensuring the safety and hygiene of food products. Food-grade silicone, thermoplastic elastomers, and polyurethane are all excellent choices for soft gripper design, offering a combination of durability, flexibility, and resistance to heat and chemicals.

Considerations for Hygienic Soft Gripper Design

When designing hygienic soft grippers for food processing applications, there are several key considerations that must be taken into account. One of the most important considerations is the surface finish of the gripper. The surface finish should be smooth and free of any imperfections that could harbor bacteria or other contaminants.

Another important consideration is the number of contact points between the gripper and the food product. The fewer the contact points, the less chance there is for contamination to occur. Additionally, the grip force of the gripper must be carefully considered. The gripper should be able to securely hold the food product without damaging it, but not so tightly that it causes deformation or damage.

Finally, it is important to consider the compatibility of the gripper with different types of food products. Different food products have different properties, such as size, shape, and texture, that can affect the performance of the gripper. A good hygienic soft gripper design should be versatile enough to handle a wide range of food products without compromising hygiene or performance.

Hygienic Design - Cleainign is Everything

There are special hygienic requirements for different foods. SoftGripping Hygienic Gripper beats them.

All parts are connected by hygienic screws and can be easily unmounted for cleaning. Our special connection of the silicon rubber fingers to the array are designed for highly hygienic requirements. Every part can be cleaned with most fierce cleaning agents.

To keep the pneumatics hygienic, the supply to the fingers is established through the arrays to the base plate and fed from there via a single input. By using appropriately sized pneumatic valves, the system is suitable for the fastest delta robots on the market.

To connect the SoftGripper to your robot, we offer a wide range of iso-standardized adapters. If you need a custom adapter for your system, please send us your technical drawing.

What Is Hygienic Design and Why you need it?

What Are You Looking For In A Hygienic Gripper?

Planning highly automated setups is a long journey. In the automation of food processing operations, one aspect tends to be neglected: Making sure all parts and details are easy to clean and to maintain.

What is often considered a prerequisite for meeting regulatory hygiene and food safety guidelines is an important topic to dive into. A thoughtful hygienic design saves you time in cleaning and maintaining facilities. Over time, even a small mistake can lead to unsanitary spaces that are a hassle to keep clean. With this in mind, we worked with our customers to develop our hygienic line.

The variety of applications had to be reflected in a gripper design. From cheese, sausage, meat fillets to fish, the objects themself have a high variance in size and weight between them. Often, a system must be designed to quickly adapt to other product dimensions of the same food product, like different type of bread and buns.

The special design minimizes gaps by reducing the number of elements used and using adapters with our new hygienic locks instead of our bayonet locks. Here, fingers can be unmounted and cleaned separately by opening the hygienic screws and simply pulling the fingers out of the array.

A second important aspect of the hygienic design covered by this product line are the beveled corners and sloped surfaces that facilitate decontamination preparation.

Incidentally, the bases and fingers are resistant to common solvent or oxidizing solutions and can even be pressure washed together in the assembled device or removed from the robot for cleaning in the dishwasher.

Replacement In Many Suction Cup Applications

Replace unhygienic suction cups: A major advantage of fingers over suction cups is the completely delimited pneumatic system. When using suction cups, a major problem lies in the open pneumatic system. Without a proper filtration system, there is a risk of litter and unsanitary contaminants entering. If the system is completely disconnected from the pneumatic supply -as it is with our fingers-, you do not have to worry about residue and dust clogging up the system or making it violating the unhygienic standards.

Case Studies

Gripper design for picking up raw chicken

There have been several case studies that have demonstrated the effectiveness of hygienic soft gripper designs in the food processing industry. One example is the gripper design for picking up raw chicken. The gripper was designed using food-grade silicone and had a smooth surface finish to prevent contamination. The gripper had a low grip force to avoid damaging the chicken in high speed handling, while still providing a secure hold. The gripper was also designed to have a minimal number of contact points with the chicken, further reducing the risk of contamination.

Gripper design for picking up vegetables

Another case study involved the design of a gripper for picking up vegetables. The gripper was designed using special silicones, which provided a secure grip without damaging the vegetables. The gripper had a soft and flexible design, allowing it to adapt to the shape of the vegetables and hold them securely. The gripper was also designed with a smooth surface finish and a minimal number of contact points to prevent contamination.

Gripper design for handling delicate food products

A third case study involved the design of a gripper for handling delicate food products, such as baked goods and pastries. The gripper was designed using polyurethane, which provided a gentle grip while still securely holding the food products. The gripper had a low grip force to avoid damaging the delicate food products, and a soft and flexible design that allowed it to adapt to the shape of the food products. The gripper was also designed to have a smooth surface finish and a minimal number of contact points to prevent contamination.

Overall, these case studies demonstrate the versatility and effectiveness of hygienic soft gripper designs in the food processing industry. With careful consideration of materials, surface finish, grip force, and compatibility with different food products, hygienic soft grippers can provide a safe and efficient solution for handling a wide range of food products.

Implementation and Integration of Hygienic Soft Gripper Design

Once the design of the hygienic soft gripper is finalized, the next step is to implement it in the food processing industry. There are two main ways to do this: retrofitting existing robots with hygienic soft grippers and incorporating hygienic soft grippers in new robot designs.

Retrofitting existing robots with hygienic soft grippers involves replacing the traditional grippers with the new hygienic soft grippers. This is a cost-effective solution as it eliminates the need to purchase new robots. It also reduces downtime as the existing robots can be retrofitted without having to take them out of operation for a long time.

On the other hand, incorporating hygienic soft grippers in new robot designs involves designing new robots that are specifically built to use these grippers. This is a more expensive solution but has the advantage of allowing for more customization and better integration of the grippers with the robot’s control system.

Regardless of which approach is chosen, it is important to ensure that the hygienic soft grippers are integrated with the robot control system. This will allow for precise control of the grippers and ensure that they operate in a safe and efficient manner.

In addition, it is important to ensure that the hygienic soft grippers are compatible with the food processing industry’s hygiene standards. This includes ensuring that they are easy to clean, do not harbor bacteria, and are made of food-grade materials.

Overall, the implementation and integration of hygienic soft gripper design in the food processing industry is an important step towards ensuring food safety and improving efficiency in the industry.

Future Trends in Hygienic Soft Gripper Design

The use of hygienic soft grippers in the food processing industry has been gaining popularity due to their ability to improve hygiene and reduce the risk of contamination. As technology continues to advance, there are several future trends that are expected to shape the design and implementation of these grippers.

One of the most significant trends is the development of new materials. Advances in material science are allowing for the creation of softer, more durable materials that are better suited for use in the food processing industry. For example, researchers are exploring the use of hydrogels, which are highly absorbent and can conform to the shape of the food product being handled.

Another trend is the use of collaborative robots, or cobots, which can work alongside human operators to improve efficiency and reduce the risk of injuries. Hygienic soft grippers are ideal for use with cobots since they are designed to be safe and gentle when handling food products.

Artificial intelligence (AI) is also expected to play a significant role in the future of hygienic soft gripper design. By incorporating AI algorithms, robots can be trained to recognize and handle different types of food products with greater accuracy and precision.

Overall, the future of hygienic soft gripper design is focused on improving hygiene, increasing efficiency, and reducing the risk of contamination in the food processing industry. As technology continues to advance, we can expect to see more innovative designs and implementations of these grippers in the years to come.

Conclusion

Hygienic soft gripper design is an important concept in the food processing industry, particularly in the context of robot applications. By using grippers that are designed to be easily cleaned and sanitized, robots can help to improve hygiene standards and minimize the risk of contamination. As the use of robots in this industry continues to grow, the development of hygienic soft gripper design will become increasingly important to ensure the safety and quality of the products being produced.

Contact

We are happy to get in touch with you! Let’s have a quick talk and find out how to automate your application. Our engineers will validate your application and provide you with test material in form of videos pictures and whitepapers:

FAQs

What are some examples of tasks that robots can perform in the food processing industry?

Robots can perform a wide range of tasks, including picking and placing products, packaging, and palletizing.

Why is maintaining hygiene important in the food processing industry?

Maintaining high levels of hygiene is critical in the food processing industry to ensure the safety and quality of the products being produced.

What are the challenges associated with using robots in the food processing industry?

The use of robots in the food processing industry presents unique challenges when it comes to maintaining hygiene standards.

What are the benefits of using hygienic soft gripper design in robot applications in the food processing industry?

Hygienic soft gripper design can help to improve hygiene standards and minimize the risk of contamination in robot applications in the food processing industry.

What materials are typically used in the development of hygienic soft gripper design?

Hygienic soft grippers are typically made of soft materials such as silicones.

Consideration

We have encountered applications from food packaging to picking scrape metal from automobile parts and our scope of application only broadens. Therefore, we are confident in our ability to find the best solution to your gripping problem.

Contact

Please feel free to get in touch via email or call so we can help you to find the right tool!

Hygienic Grippers

- Tailor-made for your application

- Perfect for high speed delta robots

- Custom made solution ready for shipping in 2 weeks