SoftGrippers vs. Suction Cups: The Ideal Solution for Hygienic Food Industry Automation

Table of Contents

Introduction

The food industry is a critical sector that demands high standards of hygiene and safety to ensure that the food produced is safe for consumption. Automation has become an essential aspect of the food industry as it can improve efficiency, reduce labor costs, and maintain consistent quality control. However, the use of traditional suction cups in automation has its limitations, particularly in handling certain food items such as bread, meats, and fish. Suction cups can introduce particles into the pneumatics, which can compromise the hygiene and safety of the food products.

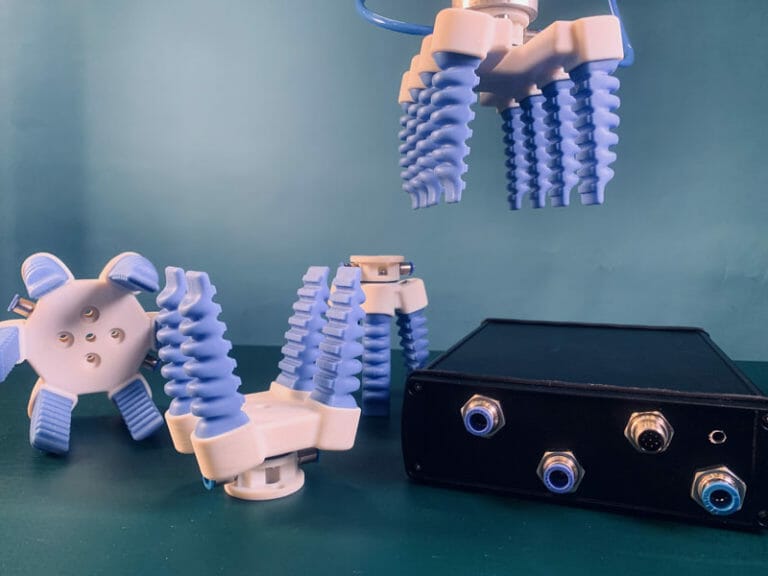

To address this issue, SoftGrippers have emerged as a more hygienic and safer alternative to suction cups in the food industry. SoftGrippers are designed with compliant fingers, adhesive grippers, and form-fitting grippers that can handle delicate and irregularly shaped items without introducing contaminants into the food products. This article will compare the features and advantages of SoftGrippers and suction cups in food industry automation, and explore the applications, safety, and ergonomics of SoftGrippers in the food industry.

SoftGrippers vs. Suction Cups

SoftGrippers and suction cups are two popular types of end-of-arm tooling used in automation for picking and placing objects. Suction cups rely on vacuum pressure to grip onto a flat, smooth surface, while SoftGrippers utilize compliant fingers, adhesive grippers, and form-fitting grippers to handle a variety of objects, including those that are irregularly shaped or delicate.

While suction cups are efficient and cost-effective in certain applications, they have limitations when it comes to handling certain types of food items. For instance, suction cups are not suitable for handling bread, meats, and fish as they can introduce particles into the pneumatics, which can compromise the hygiene and safety of the food products.

On the other hand, SoftGrippers provide a safer and more hygienic alternative for handling these types of food items. SoftGrippers have a flexible design that can conform to the shape of the food item, reducing the likelihood of contamination. Additionally, the compliance of the SoftGripper fingers allows them to conform to the food item without crushing it, maintaining the quality of the product.

Overall, SoftGrippers offer a more versatile and hygienic solution for food industry automation compared to suction cups. In the following sections, we will explore the various features and advantages of SoftGrippers in the food industry, including their compliance, adhesive grippers, and form-fitting grippers.

SoftGrippers can also incorporate suction cups into their design for additional stability and control when handling certain food items. In some cases, a suction cup can be placed in the middle of the gripper, and the soft gripping fingers can be used to stabilize the produce while the suction cup maintains its position. This approach provides a higher degree of stability and control compared to using suction cups alone, while still maintaining the advantages of SoftGrippers’ compliance and flexibility.

Alternatively, suction cups can be used as a cushion for the fingers when pressing against the food item. This method allows for the suction cup to absorb any variations in the shape of the food item, reducing the risk of damage and ensuring a consistent grip. By using a combination of suction cups and soft gripping fingers, SoftGrippers can handle even the most delicate and irregularly shaped food items with precision and care. Here is an example from the LogiMAT where fingers and a suction cup are used for a commisioning and bin picking application:

SoftGripper Features

SoftGrippers offer a range of features that make them an ideal solution for handling food items in the automation industry. These features include:

- Compliance: SoftGrippers have a compliant design that allows them to conform to the shape of the food item, reducing the likelihood of damage or contamination.

- Adhesive Grippers: SoftGrippers can incorporate adhesive grippers, which use a tacky material to provide a secure grip on the food item. This feature is especially useful when handling items with a smooth surface, such as fruits and vegetables.

- Form-Fitting Grippers: SoftGrippers can also be designed with form-fitting grippers that use a customized mold to fit the exact shape of the food item. This feature provides a high level of precision and control when handling delicate or irregularly shaped items, such as grapes or cherry tomatoes.

- Customization: SoftGrippers can be customized to meet the specific needs of a particular food item or application. This customization can include the design of the gripping fingers, the size and shape of the gripper, and the materials used in the gripper’s construction.

By incorporating these features into the design of SoftGrippers, automation engineers can create a more efficient and hygienic food handling system that is capable of handling a wide variety of food items with precision and care.

SoftGrippers in Food Industry Applications

SoftGrippers are increasingly being used in a variety of food industry applications, particularly in the areas of harvesting, packaging, and processing. One major advantage of SoftGrippers is their ability to handle delicate and irregularly shaped food items without causing damage or contamination.

In harvesting applications, SoftGrippers are used to pick fruits and vegetables from plants without damaging the produce or the plant itself. The SoftGripper’s compliant design allows it to conform to the shape of the produce, providing a gentle yet secure grip. SoftGrippers can also be customized to fit the specific shape and size of the produce being harvested, ensuring a high level of precision and efficiency.

In packaging applications, SoftGrippers are used to pick and place food items into packaging containers without damaging the product. The SoftGripper’s compliance and form-fitting capabilities ensure that the food item is held securely in place during the packaging process, reducing the likelihood of damage or contamination.

In processing applications, SoftGrippers are used to manipulate food items during the cooking or manufacturing process. SoftGrippers can be designed with a variety of gripping fingers and materials to handle different types of food items, including raw meats, fish, and bread. By incorporating SoftGrippers into the processing system, automation engineers can increase efficiency and reduce the risk of contamination.

Overall, SoftGrippers are a versatile and effective solution for handling food items in the automation industry, and their use is expected to continue to grow as automation becomes increasingly common in the food industry.

SoftGrippers in Automation

SoftGrippers are becoming increasingly popular in automation applications due to their flexibility and versatility. They can be used in a wide range of applications, from handling delicate electronic components to picking and placing food items in the food industry. SoftGrippers are particularly useful in situations where the items being handled are irregularly shaped, fragile, or otherwise difficult to grip with traditional robotic grippers.

One key advantage of SoftGrippers in automation is their ability to conform to the shape of the object being handled. This allows for a more secure grip, reducing the likelihood of dropping or damaging the object. SoftGrippers can also be designed with a variety of fingers and materials to handle different types of objects, from soft fabrics to hard plastics.

Another advantage of SoftGrippers is their compliance. Unlike traditional robotic grippers, which can be rigid and inflexible, SoftGrippers are designed to be compliant, allowing them to adapt to the shape of the object being handled. This compliance also makes them more forgiving, reducing the likelihood of damage to the object being handled.

SoftGrippers can be used in a wide range of automation applications, including pick-and-place, assembly, and inspection. They can also be integrated with other automation technologies, such as vision systems and force sensors, to improve precision and efficiency.

In summary, SoftGrippers are a valuable tool in the automation industry, offering flexibility, compliance, and precision. Their use is expected to continue to grow as automation becomes increasingly prevalent in a variety of industries.

Safety and Ergonomics

When it comes to automation, safety is always a top priority. SoftGrippers are designed with safety in mind, with features such as compliance and flexibility that reduce the risk of injury to both the operator and the product being handled.

SoftGrippers also offer ergonomic benefits in automation applications. Traditional robotic grippers can be bulky and heavy, which can be problematic in situations where the operator needs to handle the robot or interact with it in some way. SoftGrippers are typically lighter and more compact, making them easier to handle and reducing the risk of operator injury.

In addition, SoftGrippers can be designed to work with a variety of gripping styles, from pinch grips to full hand grips. This allows for a more natural and comfortable programming effort for the operator, reducing the risk of strain or injury over testing periods.

SoftGrippers can also be designed with custom fingers and materials to handle specific products, further reducing the risk of injury or damage to the product. For example, SoftGrippers used in the food industry may be designed with fingers made from food-grade materials that are safe for handling food products.

Overall, SoftGrippers offer a safe and ergonomic solution for automation applications. When designed and used properly, they can reduce the risk of injury and damage to both the operator and the product being handled.

SoftGrippers in Other Industries

While SoftGrippers have many applications in the food industry, they are also finding use in other industries where delicate or irregularly shaped objects need to be handled.

In the consumer goods industry, SoftGrippers are being used to handle delicate items such as glassware, ceramics, and electronics. SoftGrippers can be designed with custom fingers and materials to provide a gentle, yet secure grip on these fragile items.

In the medical industry, SoftGrippers are being used to handle delicate instruments and devices. SoftGrippers can be designed with fingers that are compatible with medical-grade materials, reducing the risk of contamination and damage to sensitive equipment.

In the logistics industry, SoftGrippers are being used to handle irregularly shaped objects such as packages and parcels. SoftGrippers can be designed with custom fingers that conform to the shape of the object, providing a secure grip that prevents slipping and damage.

Overall, SoftGrippers offer a versatile and adaptable solution for handling delicate and irregularly shaped objects in a variety of industries. With custom designs and materials, SoftGrippers can be tailored to the specific needs of each application, providing a safe and efficient handling solution.

Further Questions

A quick Q&A of all questions to have a good grasp on the topic:

Why does a suction cup not stick on a rough surface?

Suction cups require a completely airtight seal to work effectively. Rough surfaces create small pockets of air that break the seal, making it difficult for the suction cup to stick.

What surfaces are best for suction cups?

Suction cups work best on smooth and non-porous surfaces such as glass, ceramic, or plastic. The surface must be clean and free of any dirt or debris to ensure a proper seal.

How do you get a suction cup to stick to an uneven surface?

For uneven surfaces, it may be necessary to use a suction cup alternative such as SoftGrippers. These grippers use a combination of soft materials and vacuum suction to create a secure grip on irregularly shaped objects. Alternatively, a suction cup with a larger surface area may be used to create a stronger seal on an uneven surface.

How do SoftGrippers compare to traditional robotic grippers?

SoftGrippers offer several advantages over traditional robotic grippers, including the ability to grip irregularly shaped objects, greater flexibility, and increased safety. They are also more cost-effective and easier to maintain.

Can SoftGrippers handle delicate objects?

Yes, SoftGrippers are specifically designed to handle delicate objects such as fruits and vegetables without damaging them. The soft and pliable materials used in SoftGrippers conform to the shape of the object being gripped, providing a secure yet gentle grip.

What types of industries can benefit from using SoftGrippers?

SoftGrippers are useful in a variety of industries, including food processing, packaging, and manufacturing. They are particularly well-suited for handling delicate or irregularly shaped objects that cannot be easily gripped by traditional robotic grippers.

Do suction cups work on any surface?

Suction cups work best on smooth and non-porous surfaces such as glass or ceramic. They are less effective on rough or porous surfaces such as wood or concrete.

Can suction cups be used in wet environments?

SoftGrippers are useful in a variety of industries, including food processing, packaging, and manufacturing. They are particularly well-suited for handling delicate or irregularly shaped objects that cannot be easily gripped by traditional robotic grippers.

What is the maximum weight that SoftGrippers can handle?

The maximum weight that SoftGrippers can handle depends on the specific model and configuration. Some SoftGripper GorillaFinger models can handle objects weighing up to 5 kg in high-speed mode in combination with suction cups, while others are designed for smaller objects. It is important to choose the appropriate SoftGripper model for the specific application.

Conclusion

SoftGrippers are an innovative solution for handling delicate and irregularly shaped objects in the food industry and beyond. While suction cups have limitations in certain applications, SoftGrippers offer a versatile and customizable alternative that can be designed to meet the unique needs of each application.

With the ability to handle a wide range of produce and materials, SoftGrippers are becoming increasingly popular in the food industry, where they offer benefits such as improved hygiene and reduced waste. In addition, SoftGrippers are finding use in a variety of other industries where delicate or irregularly shaped objects need to be handled.

As automation continues to transform industries around the world, SoftGrippers are poised to play a key role in the future of robotics and automation. By providing a safe, efficient, and adaptable solution for handling delicate objects, SoftGrippers offer a powerful tool for improving productivity, reducing waste, and improving safety in a variety of industries.

Overall, SoftGrippers are a promising technology that offers significant benefits for the food industry and beyond. As the technology continues to evolve and improve, SoftGrippers are likely to become an increasingly important tool for automation engineers and other professionals who are seeking to optimize their operations and improve their bottom line.

Contact

We are happy to get in touch with you! Let’s have a quick talk and find out how to automate your application. Our engineers will validate your application and provide you with test material in form of videos pictures and whitepapers: