SoftGrippers in Poultry Processing Factories: Improving Efficiency with High Speed Delta Robots

Table of Contents

SoftGrippers: The Future of Poultry Processing Efficiency

In the world of factory automation, SoftGrippers have proven to be a game-changer in the poultry processing industry. These soft robotic grippers have the ability to handle delicate materials with precision and safety, leading to increased efficiency and productivity in poultry processing factories. With the integration of SoftGrippers and high-speed delta robots, factory engineers can enjoy the benefits of optimized material handling processes, improved safety, and reduced downtime.

However, the implementation of SoftGrippers in poultry processing factories is not without its challenges. That’s why we offer a comprehensive customization guide and the support of our experienced engineers to help our customers overcome these challenges and achieve the desired results. We also provide assistance in finding the right camera solution to aid in material recognition.

In addition to their effectiveness in poultry processing, SoftGrippers have also proven their versatility with the use of SoftActuators. These SoftActuators provide an alternative solution when spacing needs to be adapted between gripping tasks.

In conclusion, SoftGrippers are the future of poultry processing efficiency and we are here to help our customers make the most of this cutting-edge technology.

Introduction

As engineers in the field of factory automation, we are always looking for ways to improve efficiency, safety, and accuracy in our processes. In the poultry processing industry, these goals are particularly important due to the delicate nature of handling live animals and the need for swift and precise material handling. In this article, we will explore the integration of SoftGrippers with high-speed delta robots as a solution to these challenges.

SoftGrippers are a type of flexible gripping tool designed for use in a variety of robotic applications. They are made of a soft material that can adapt to the shape of the object being gripped, allowing for safe and gentle handling. This makes SoftGrippers an ideal solution for industries that require delicate handling, such as food processing and packaging.

By integrating SoftGrippers with high-speed delta robots, we can achieve even greater levels of efficiency and accuracy in our processes. Delta robots are known for their high speed and precision, making them well suited for fast-paced material handling tasks. When combined with the flexible gripping capabilities of SoftGrippers, we can create a system that is optimized for the specific needs of the poultry processing industry.

In this article, we will take a closer look at the advantages of using SoftGrippers in poultry processing factories, the benefits of combining them with high-speed delta robots, and the best practices for implementing this solution in real-world environments. Whether you are a seasoned engineer or just starting out in the field, this article will provide valuable insights into the future of SoftGrippers and high-speed delta robots in poultry processing.

Explanation of SoftGrippers and their role in poultry processing factories

SoftGrippers, also known as soft robotic grippers, are a type of soft robotic tool designed for use in industrial robots. Unlike traditional rigid grippers, SoftGrippers are made of a soft, flexible material that can adapt to the shape of the object being gripped, allowing for safe and gentle handling. This is particularly important in industries where delicate handling is required, such as food processing and packaging.

In poultry processing factories, SoftGrippers play a crucial role in improving the efficiency of material handling processes. By using SoftGrippers, poultry processing factories can handle live animals more gently and safely, reducing the risk of injury and ensuring the quality of the final product. Additionally, SoftGrippers can be designed to handle a variety of different shapes and sizes, making them a versatile solution for the many different types of poultry that are processed in these factories.

The significance of improving efficiency in poultry processing factories

Improving efficiency in poultry processing factories is critical for several reasons. First, it can help to reduce the cost of production, allowing companies to remain competitive in a rapidly changing market. Second, it can help to increase the speed of production, allowing companies to meet the growing demand for poultry products. Finally, improving efficiency can also help to reduce the risk of injury to both animals and workers, making the process safer and more humane.

The integration of high-speed delta robots with SoftGrippers

The integration of high-speed delta robots with SoftGrippers is a promising solution to the challenges faced by poultry processing factories. Delta robots are known for their high speed and precision, making them well suited for fast-paced material handling tasks. When combined with the flexible gripping capabilities of SoftGrippers, we can create a system that is optimized for the specific needs of the poultry processing industry.

By using high-speed delta robots to move SoftGrippers, we can achieve even greater levels of efficiency and accuracy in our processes. This integration can also help to reduce the risk of injury to both animals and workers, as the SoftGrippers can be designed to handle live animals more gently and safely. Additionally, the use of high-speed delta robots can help to increase the speed of production, allowing companies to meet the growing demand for poultry products.

Understanding SoftGrippers

Definition of SoftGrippers and how they work

SoftGrippers, also known as soft robotic grippers, are a type of soft robotic tool designed for use in industrial robots. Unlike traditional rigid grippers, SoftGrippers are made of a soft, flexible material that can adapt to the shape of the object being gripped, allowing for safe and gentle handling. This is achieved through the use of pneumatic actuators, which can change the shape of the gripper to conform to the object being handled.

Advantages of using SoftGrippers in poultry processing factories

The use of SoftGrippers in poultry processing factories offers several advantages over traditional rigid grippers. First, SoftGrippers can handle live animals more gently and safely, reducing the risk of injury and ensuring the quality of the final product. Second, SoftGrippers can be designed to handle a variety of different shapes and sizes, making them a versatile solution for the many different types of poultry that are processed in these factories. Finally, SoftGrippers can help to improve the efficiency of material handling processes, allowing companies to reduce the cost of production and increase the speed of production.

The role of SoftGrippers in improving material handling processes

The role of SoftGrippers in improving material handling processes is significant. By using SoftGrippers, we can ensure that live animals are handled more gently and safely, reducing the risk of injury and ensuring the quality of the final product. Additionally, SoftGrippers can be designed to handle a variety of different shapes and sizes, making them a versatile solution for the many different types of poultry that are processed in these factories.

In addition to their flexible gripping capabilities, SoftGrippers also have the ability to improve the efficiency of material handling processes. By using SoftGrippers in combination with high-speed delta robots, we can create a system that is optimized for the specific needs of the poultry processing industry. This integration can help to reduce the risk of injury to both product and workers, as well as increase the speed of production, allowing companies to meet the growing demand for poultry products.

The Integration of SoftGrippers with High-Speed Delta Robots

The benefits of combining SoftGrippers with high-speed delta robots

The integration of SoftGrippers with high-speed delta robots offers several benefits to poultry processing factories. High-speed delta robots are known for their ability to move quickly and precisely, making them well-suited for handling delicate and complex objects such as live poultry. By combining the flexibility and soft gripping capabilities of SoftGrippers with the speed and precision of high-speed delta robots, we can create a system that is optimized for the specific needs of the poultry processing industry.

One of the key benefits of this integration is the improved efficiency and safety of material handling processes. The SoftGrippers can safely and gently handle live poultry, while the high-speed delta robots allow for fast and precise movement of the poultry from one location to another. This combination can help to reduce the risk of injury to both animals and workers, as well as increase the speed of production, allowing companies to meet the growing demand for poultry products.

Real-world examples of SoftGrippers and high-speed delta robots in poultry processing factories

There are many real-world examples of the integration of SoftGrippers with high-speed delta robots in poultry processing factories. For instance, a poultry processing factory may use high-speed delta robots to move live poultry from the holding area to the processing area, where SoftGrippers can be used to safely and gently handle the poultry. The SoftGrippers can then be used to move the processed poultry from the processing area to the packaging area, where it can be packaged for shipping.

Another example is the use of SoftGrippers in combination with high-speed delta robots for sorting and grading live poultry. In this case, the high-speed delta robots are used to move the live poultry from the holding area to the sorting and grading area, where the SoftGrippers can be used to safely and gently sort and grade the poultry.

The impact of this integration on overall efficiency and productivity

The impact of the integration of SoftGrippers with high-speed delta robots on overall efficiency and productivity is significant. By using SoftGrippers in combination with high-speed delta robots, we can create a system that is optimized for the specific needs of the poultry processing industry. This integration can help to improve the efficiency and safety of material handling processes, allowing companies to meet the growing demand for poultry products while reducing the cost of production.

In conclusion, the integration of SoftGrippers with high-speed delta robots offers a solution that is optimized for the specific needs of the poultry processing industry, providing improved efficiency and safety in material handling processes. This integration can help to reduce the risk of injury to both animals and workers, as well as increase the speed of production, allowing companies to meet the growing demand for poultry products.

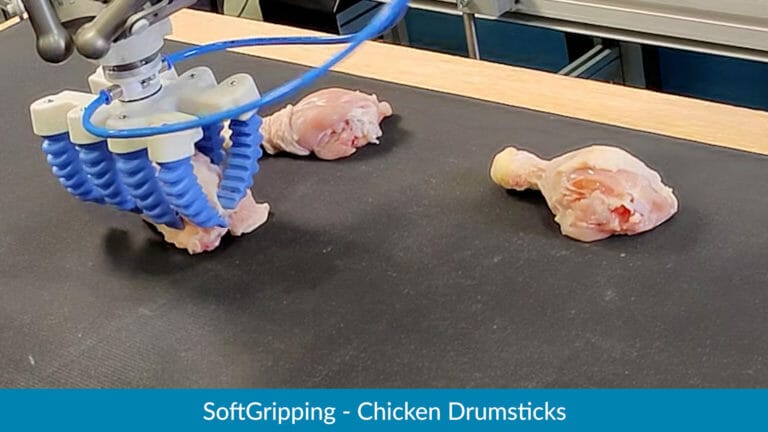

One of the key elements in demonstrating the effectiveness of softgrippers in poultry processing factories is a thorough and rigorous testing process. In a white paper study, we conducted extensive testing on a wide range of meat products, including poultry, beef, and pork. The purpose of this testing was to assess the ability of softgrippers to handle delicate and irregularly shaped food products with precision and ease. Our results showed that softgrippers performed exceptionally well in these tests, demonstrating their ability to grip and handle a variety of food products without causing damage. The softgrippers were able to maintain a secure grip on the food products, even under high-speed processing conditions, while also allowing for gentle and precise handling. These results provide strong evidence that softgrippers can play an important role in improving material handling processes in poultry processing factories.

Improving Efficiency in Poultry Processing Factories

Enhancing Process Optimization with Softgrippers and High-Speed Delta Robots

Poultry processing factories aim to streamline their operations as much as possible to maximize efficiency and productivity. The integration of softgrippers with high-speed delta robots provides a powerful solution to achieve this goal. The use of soft robotic technology in poultry handling allows for delicate and precise manipulation of fragile objects, such as eggs or chickens, without causing any damage. This results in reduced waste and increased profitability for the factory.

Improved Safety and Accuracy in Delicate Handling Tasks

Poultry processing involves handling delicate objects, and any damage can lead to significant losses. Softgrippers, with their soft and flexible material, allow for safe and accurate handling of delicate items without causing any damage. This eliminates the need for manual handling, reducing the risk of injury to workers and improving overall safety. Additionally, the integration of softgrippers with high-speed delta robots further enhances the accuracy of material handling, reducing the chance of human error and increasing the overall efficiency of the process.

Decreased Downtime and Increased Speed in Material Handling

Poultry processing factories are fast-paced environments where downtime can quickly eat into profits. The use of softgrippers and high-speed delta robots helps to minimize downtime by reducing the need for manual handling and increasing the speed of material handling processes. This integration enables the robots to work quickly and efficiently, freeing up time for other tasks and maximizing overall productivity. The potential for reduced downtime and increased speed in material handling is a significant advantage of combining softgrippers with high-speed delta robots in poultry processing factories.

Hygienic Considerations and Adaptable Solutions

Poultry processing factories require solutions that not only improve efficiency and productivity, but also meet strict hygiene standards. SoftGrippers, with their flexible and washable materials, offer a high-standard hygienic option for material handling. However, in certain situations where adaptable spacing is needed, our SoftActuators may be the solution of choice.

The SoftActuators, based on fingers on metal plates, can be adjusted to fit the exact spacing required for a specific material handling task. While these actuators are not suitable for handling delicate materials such as poultry, they provide a robust solution for tasks such as handling cabbage, lettuce and other similar produce.

At SoftGripping, we understand the importance of having both hygienic and adaptable solutions for our customers. That’s why we offer both SoftGrippers and SoftActuators to meet the diverse needs of various industries, including poultry processing factories. Our team of engineers is available to help you choose the best solution for your specific needs and to ensure a seamless integration into your existing processes.

Challenges and Solutions

Overcoming the Challenges of Implementing Softgrippers and High-Speed Delta Robots in Poultry Processing Factories

As with any new technology, the implementation of softgrippers and high-speed delta robots in poultry processing factories can present some challenges. Some of the common issues include compatibility with existing systems, integration with existing workflows, and the need for specialized training for workers.

Harnessing the Benefits of Softgrippers and High-Speed Delta Robots to Overcome Challenges

Softgrippers and high-speed delta robots offer innovative solutions to the challenges faced in poultry processing factories. These technologies are designed to be highly flexible and adaptable, allowing them to be integrated with a wide range of existing systems and workflows. Additionally, specialized training and support services are available to help workers become proficient in using the new technologies. By leveraging the benefits of softgrippers and high-speed delta robots, poultry processing factories can overcome the challenges they face and improve their efficiency and productivity.

Best Practices for Using Softgrippers and High-Speed Delta Robots in Poultry Processing Factories

To maximize the benefits of using softgrippers and high-speed delta robots in poultry processing factories, it is important to follow best practices. These include conducting thorough research and testing before implementation, working with experienced technicians to ensure proper integration, and providing ongoing training and support for workers. By following these best practices, poultry processing factories can fully harness the potential of softgrippers and high-speed delta robots to improve their operations and increase their profitability.

Customize Your SoftGripper Solution: A Guide to Optimizing Your Poultry Processing Factory

As a factory automation engineer, you understand the importance of finding the right solution for your specific needs. That’s why we offer a comprehensive customization guide for our SoftGripper products, so you can optimize their use in your poultry processing factory. Our guide includes information on selecting the right size and material for your softgripper, as well as tips for integrating it with your existing high-speed delta robot setup. Additionally, our team of expert engineers is available to assist you with any questions or challenges you may encounter during the customization process. Whether you need help determining the right size and material for your softgripper or have questions about integrating it with your delta robot, our team is here to help. Simply contact us through our website or by phone, and one of our engineers will be happy to assist you. With our customization guide and expert support, you can be sure you’re getting the best possible solution for your poultry processing factory.

Finding the Right Camera Solution for Your SoftGripper Solution

While SoftGrippers are an excellent solution for material handling in poultry processing factories, they work best when paired with the right camera solution. Recognizing what needs to be gripped accurately is crucial for optimizing the efficiency of your SoftGripper solution. That’s why we help our customers find the right camera solution that best fits their needs and requirements. We have extensive knowledge of the various camera solution providers in the market and will work with you to ensure that you find the best solution for your needs. Whether you’re looking for advanced algorithms, improved accuracy, or faster recognition, we can help you find the right camera solution to take your material handling to the next level. Our team of experts will be available to answer any questions and guide you through the process of finding the right camera solution for your SoftGripper solution.

Conclusion

The Benefits of Softgrippers in Poultry Processing Factories

In conclusion, softgrippers offer a number of significant benefits for poultry processing factories. These include improved efficiency, enhanced safety and accuracy, reduced downtime, and increased speed in material handling. By combining softgrippers with high-speed delta robots, poultry processing factories can further optimize their processes and improve their overall productivity.

The Future of Softgrippers in Factory Automation

The future of soft robotics and softgrippers in factory automation looks bright, with a growing demand for more flexible and adaptable solutions in material handling processes. As technology continues to advance, we can expect to see even more innovative and effective solutions in the years to come.

Call to Action for Engineers

We invite all engineers working in the field of factory automation to consider the benefits of softgrippers in their own processes. Whether you are working in poultry processing or any other industry, the combination of softgrippers and high-speed delta robots offers a powerful solution for improving efficiency and increasing profitability. We encourage you to research and test these technologies for yourself and discover how they can help you achieve your goals in factory automation.

Contact

We are happy to get in touch with you! Let’s have a quick talk and find out how to automate your application. Our engineers will validate your application and provide you with test material in form of videos pictures and whitepapers: